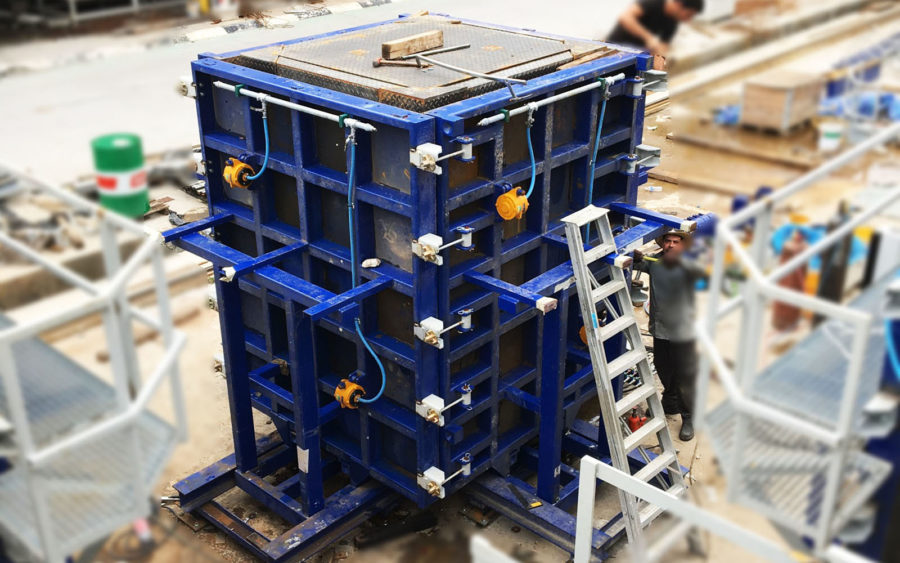

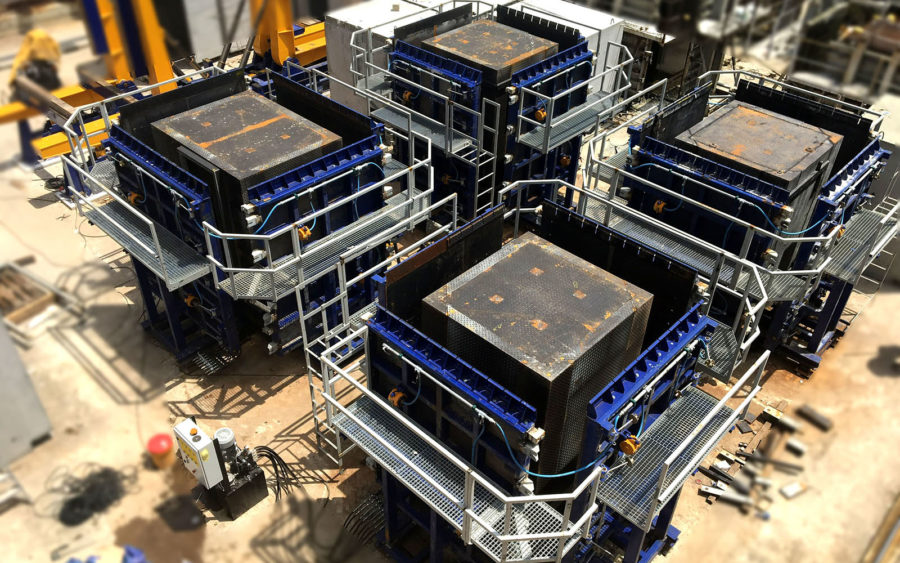

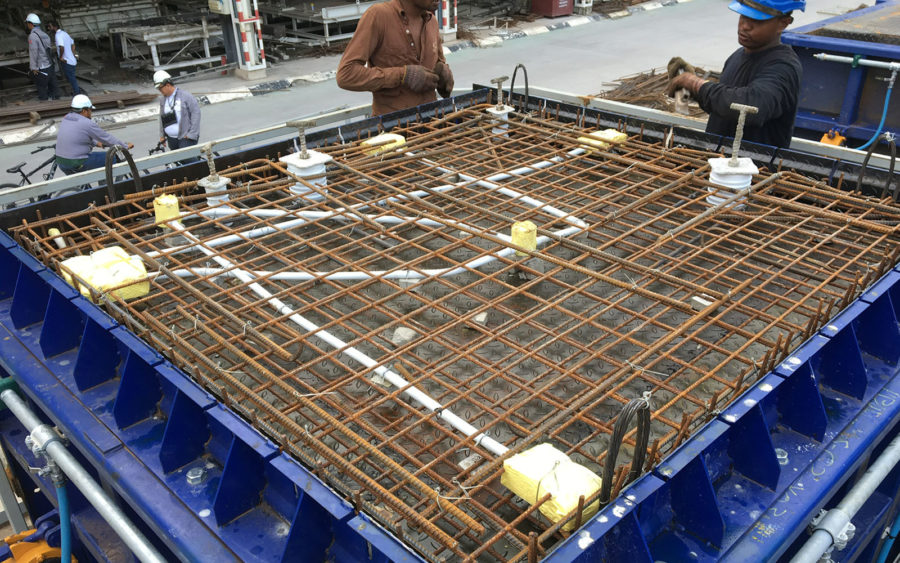

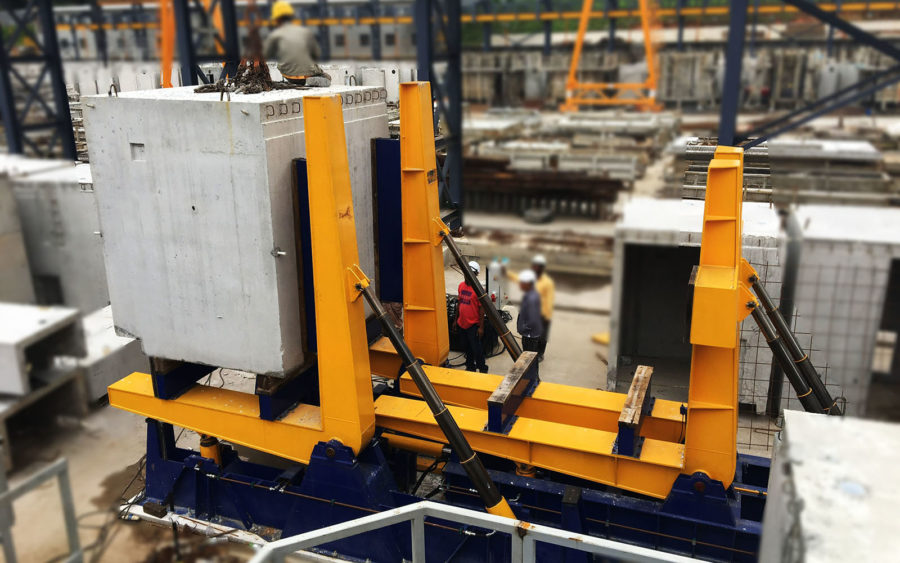

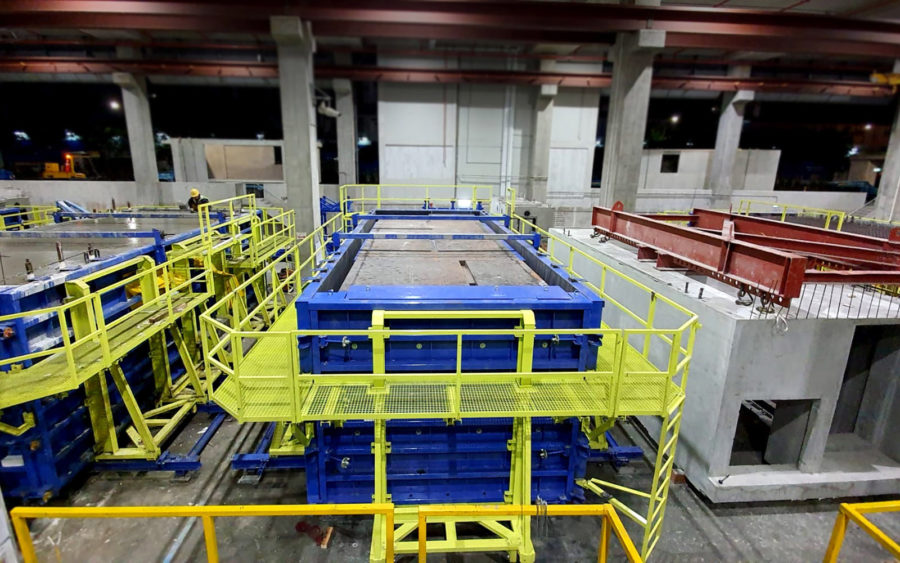

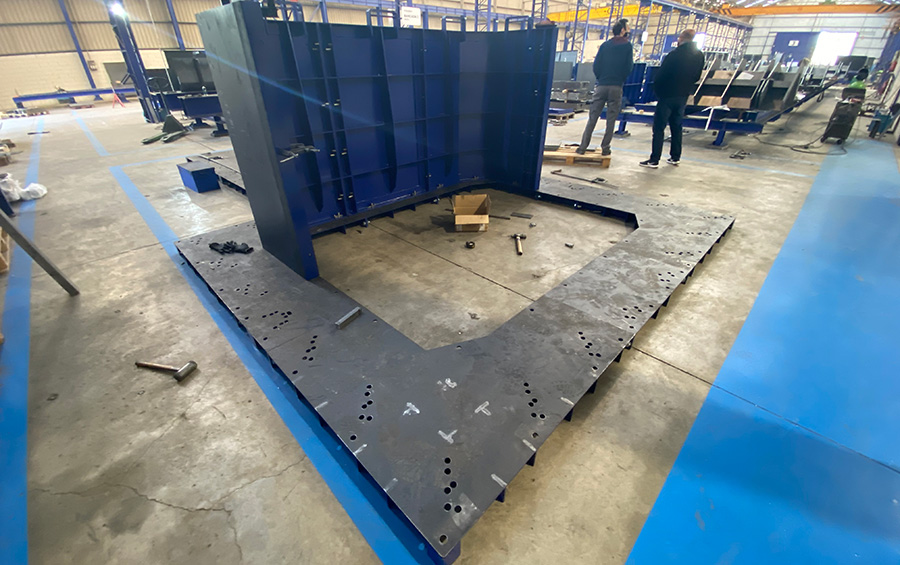

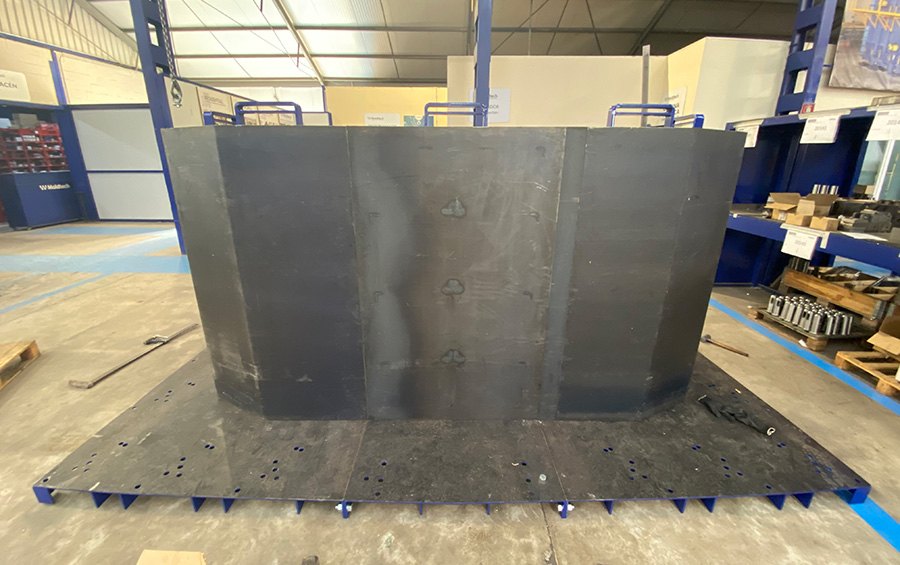

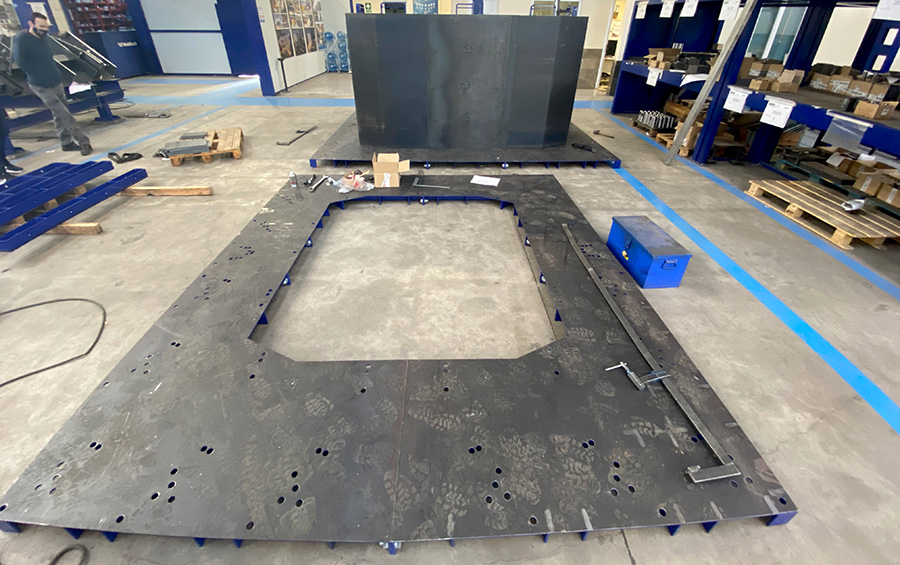

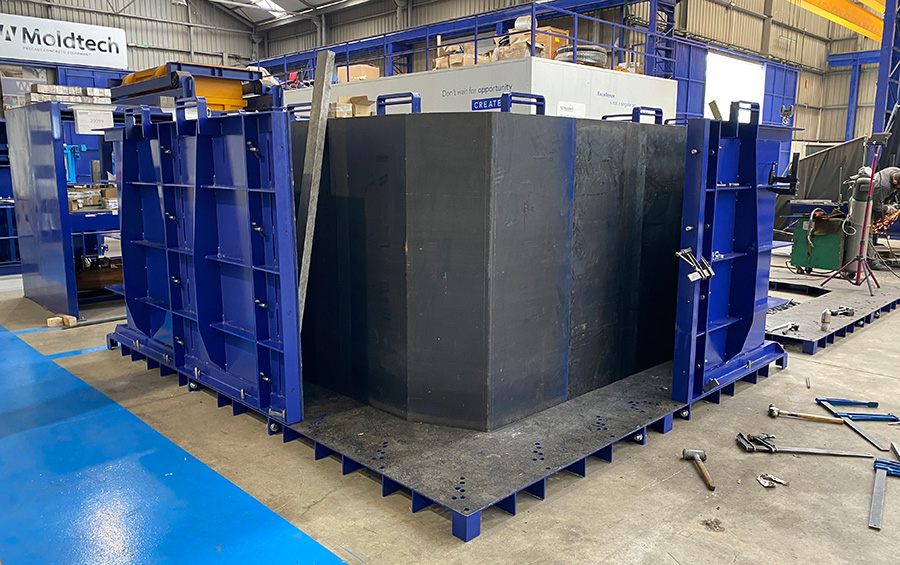

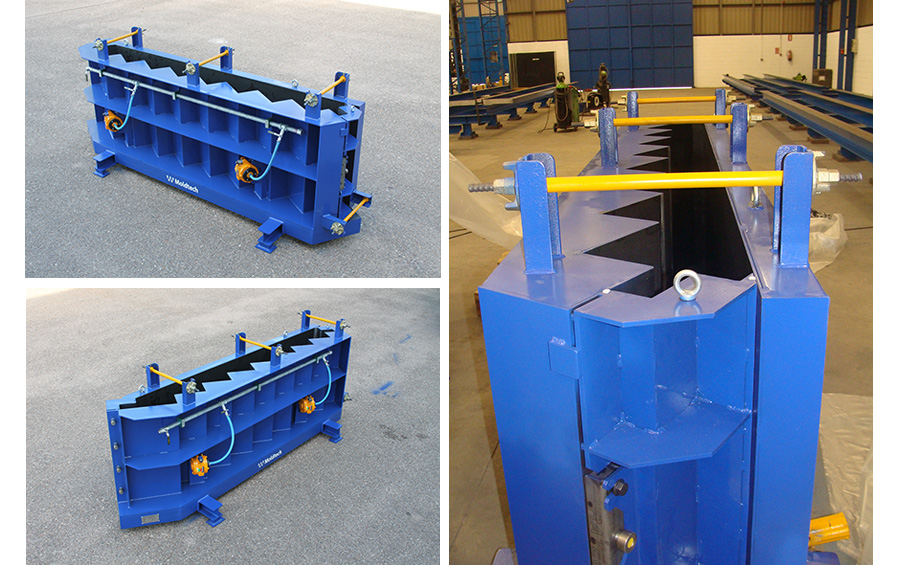

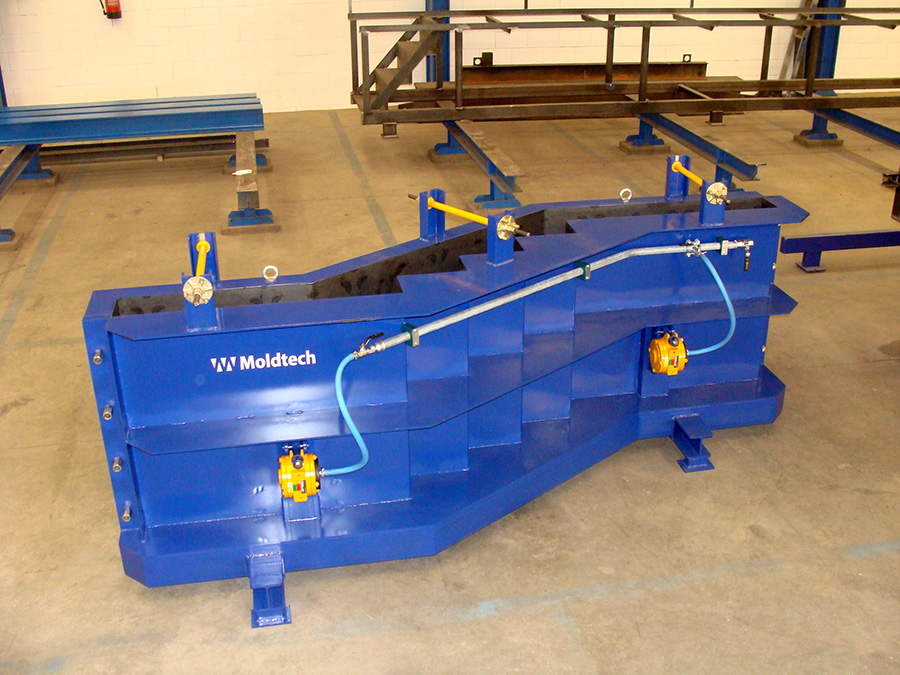

SUPPLY

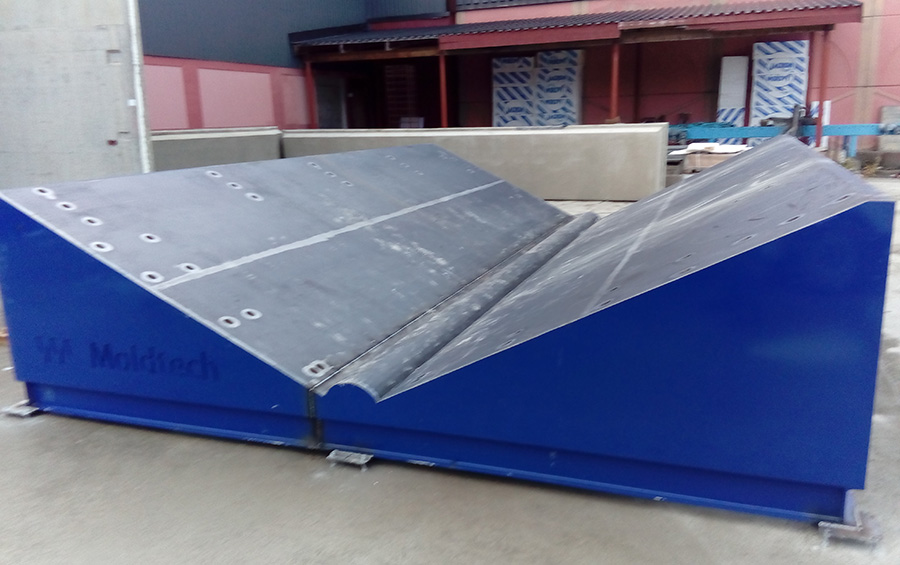

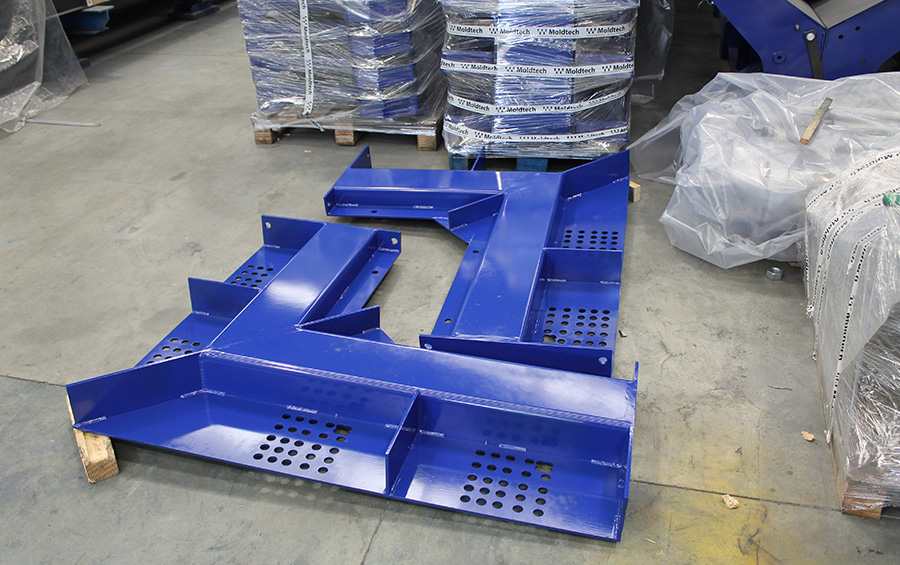

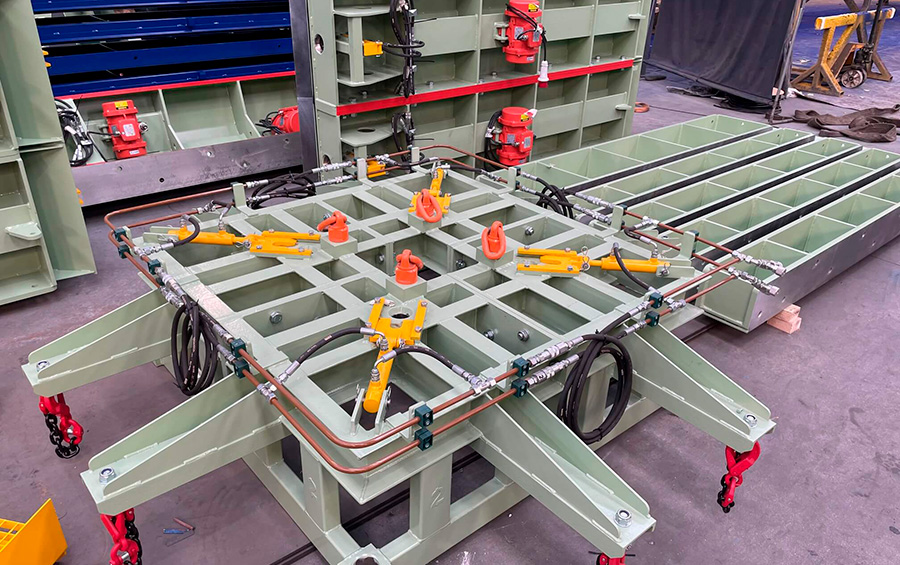

‘MT20’ mould for making dry cast box culverts with capacity for 11 different sizes ranging from1.8 m (5.9 ft) span x 1.5 m (4.9 ft) rise up to 3 m (9.8 ft) span x 3 m (9.8 ft) rise.

All with a length of 2 m (9.8ft).

Productivity of 25 culverts in 2 work shifts.

‘MT20’ DRY CAST BOX CULVERT EQUIPMENT

2018 – INDIA

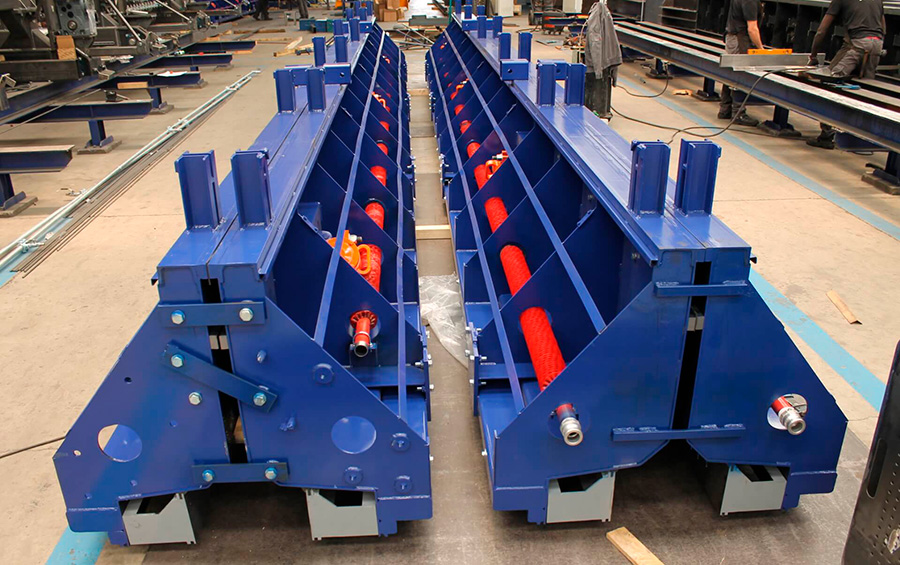

SUPPLY

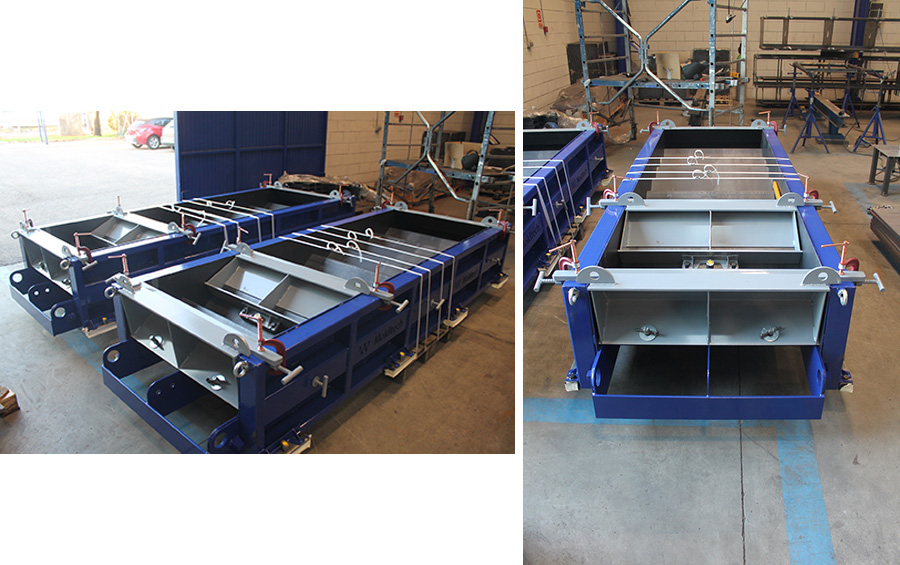

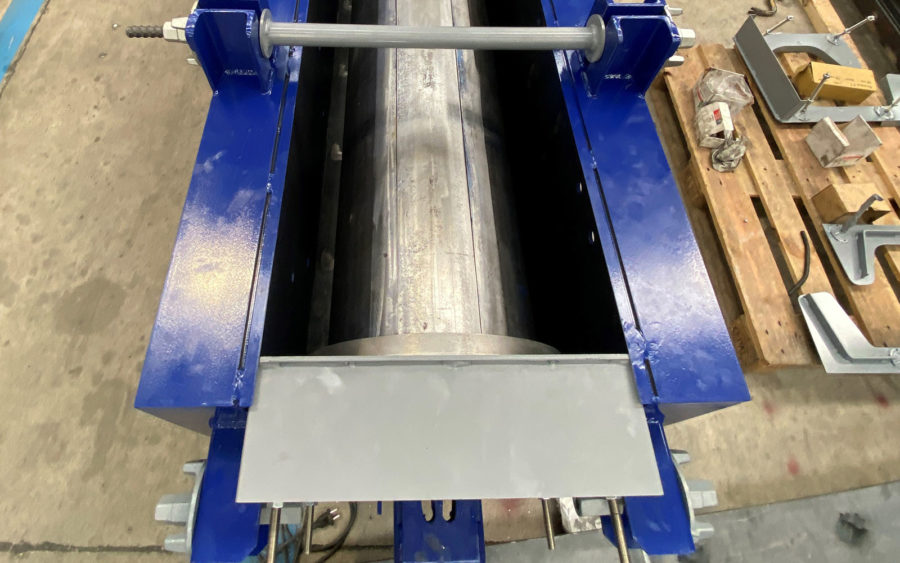

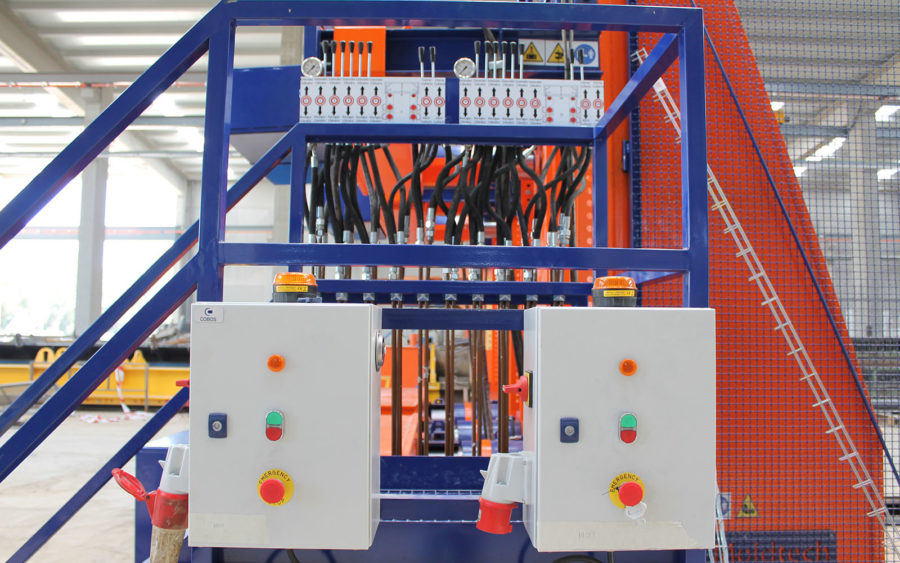

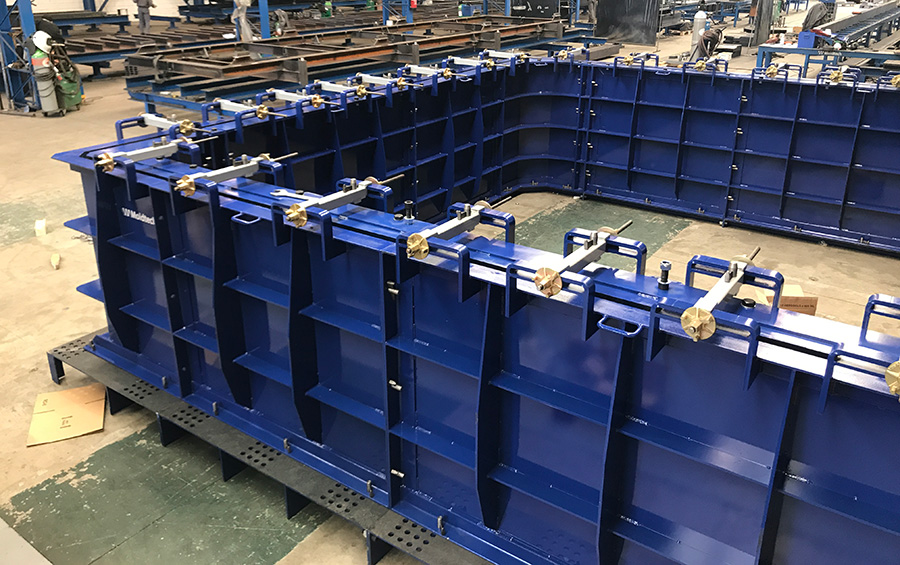

Carrousel for the production of 250 hollow core columns per day.

Columns of length from 2.6 to 3.6 m (8.6 x 12 ft) and width between 25 and 90 cm (0.98 x 2.12 ft) (1 to 3 cores).

Totally automated line consisting of 56 pallets including hydraulic system for the positioning of side shuttering and inserting and extraction of the cores.

The line features double station for pouring, vibrating and screeding.

CARROUSEL LINE FOR HOLLOW CORE COLUMNS (I)

2018 – INDIA

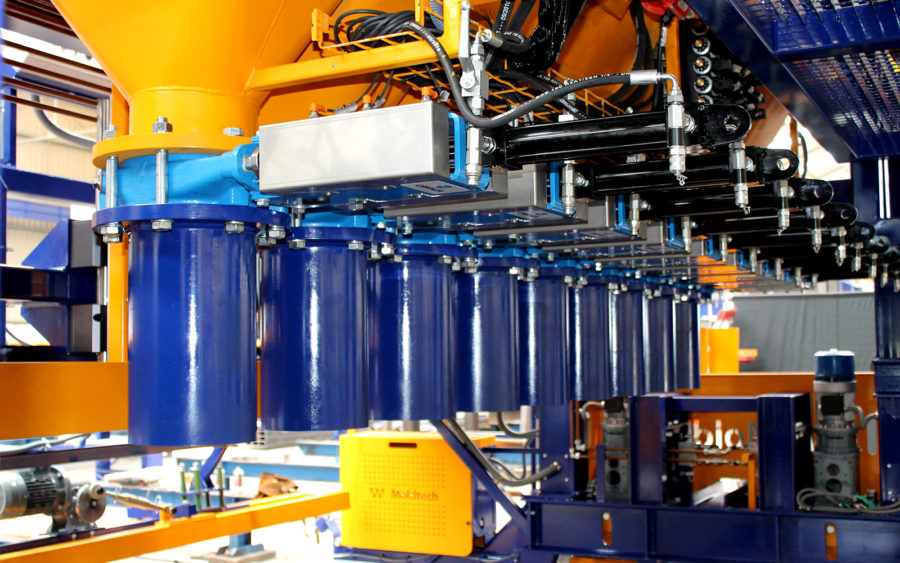

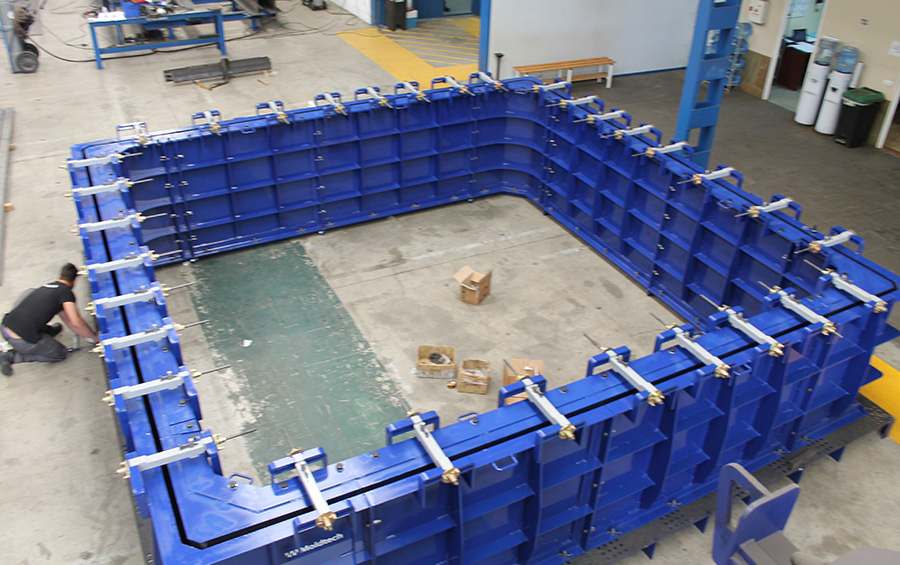

SUPPLY

Carrousel for the production of 250 hollow core columns per day.

Columns of length from 2.6 to 3.6 m (8.6 x 12 ft) and width between 25 and 90 cm (0.98 x 2.12 ft) (1 to 3 cores).

Totally automated line consisting of 56 pallets including hydraulic system for the positioning of side shuttering and inserting and extraction of the cores.

The line features double station for pouring, vibrating and screeding.

CARROUSEL LINE FOR HOLLOW CORE COLUMNS (II)

2018 – INDIA

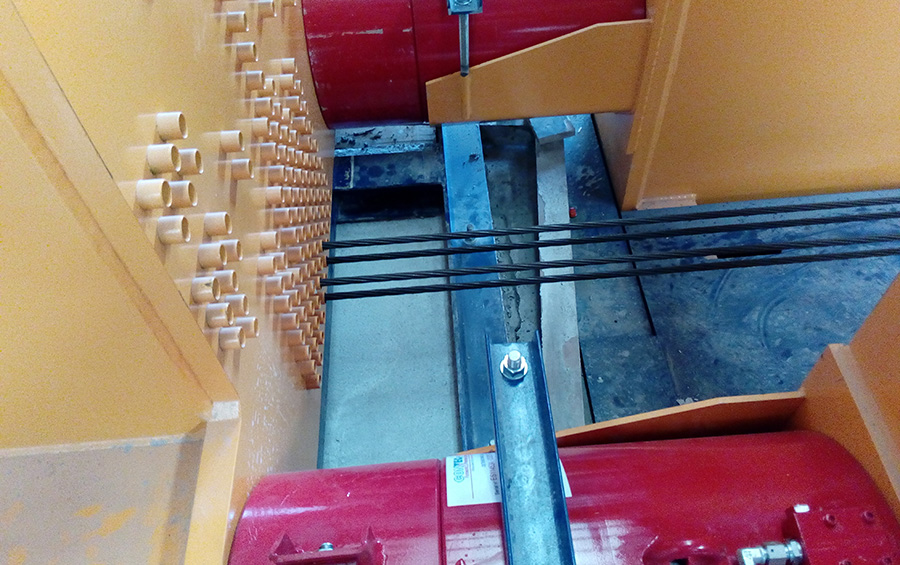

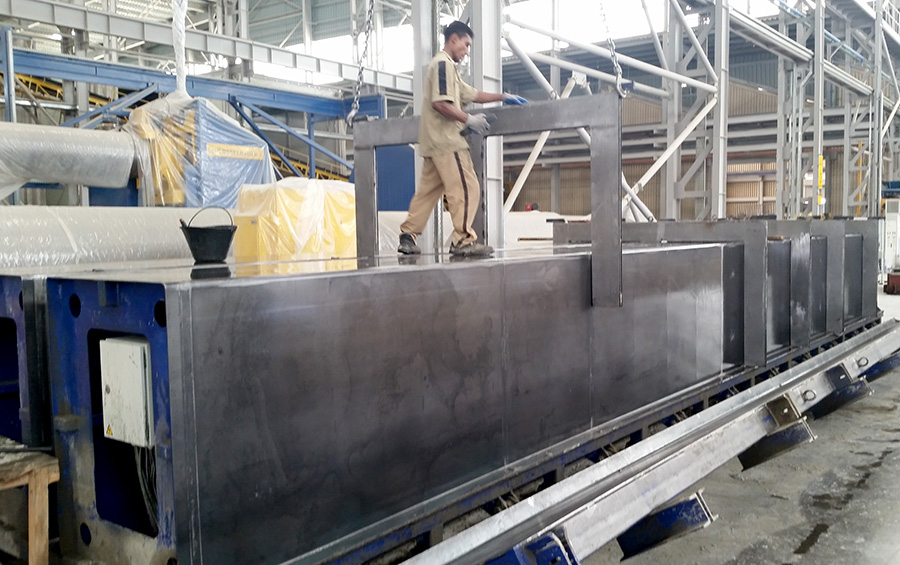

SUPPLY

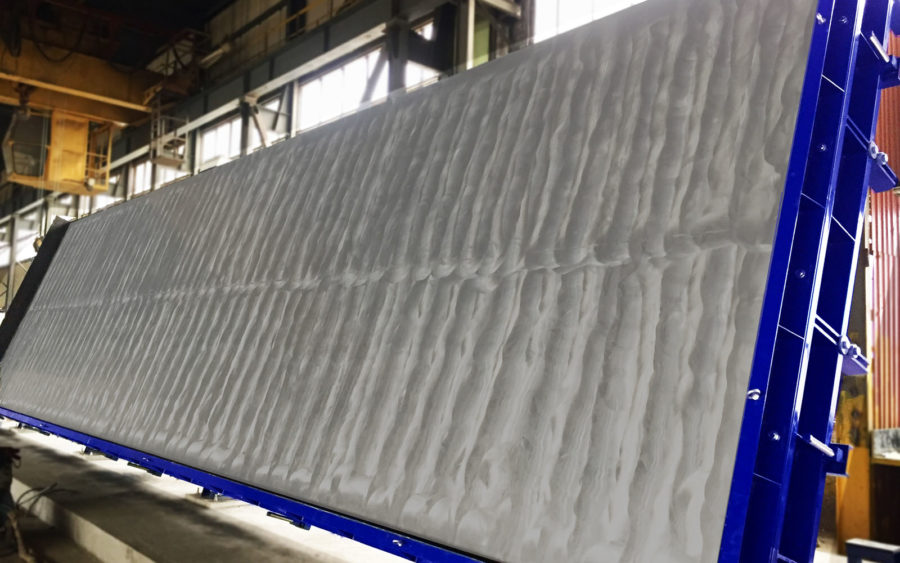

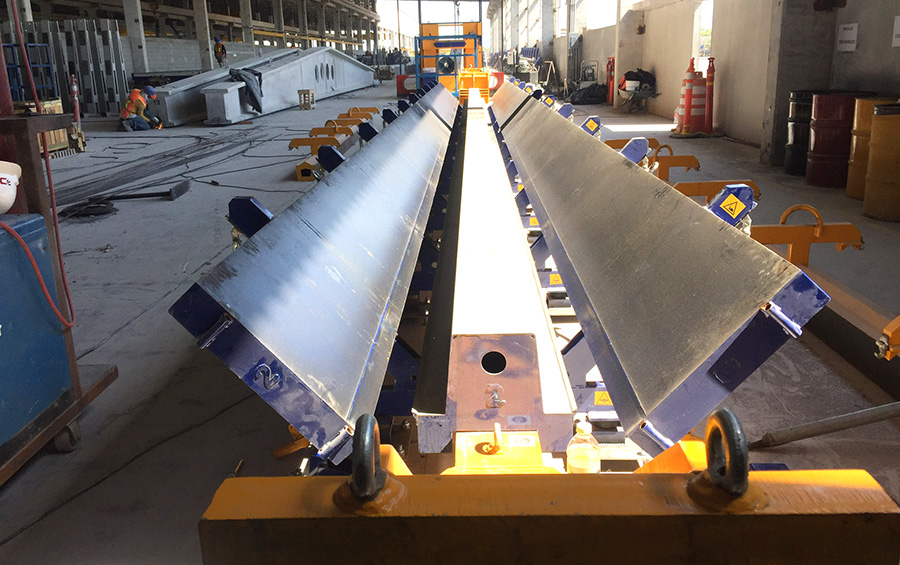

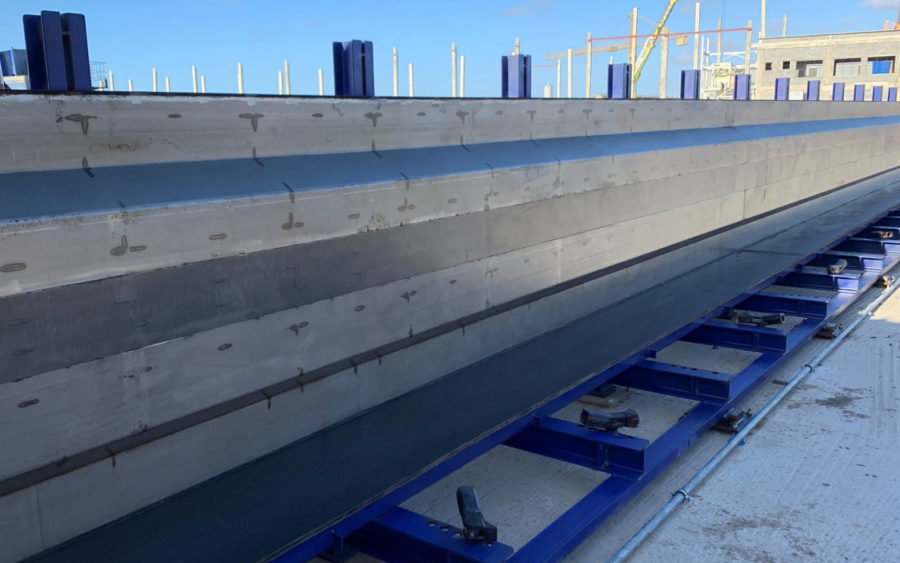

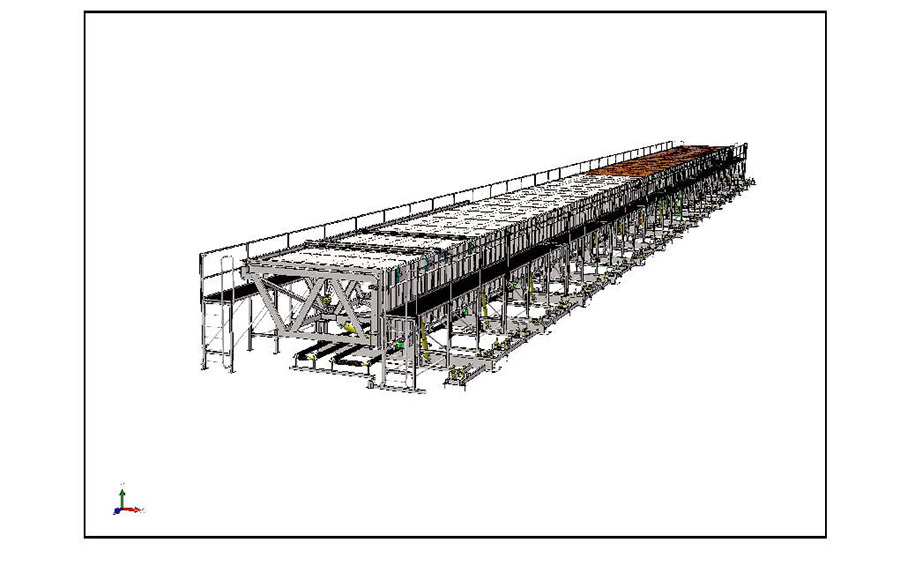

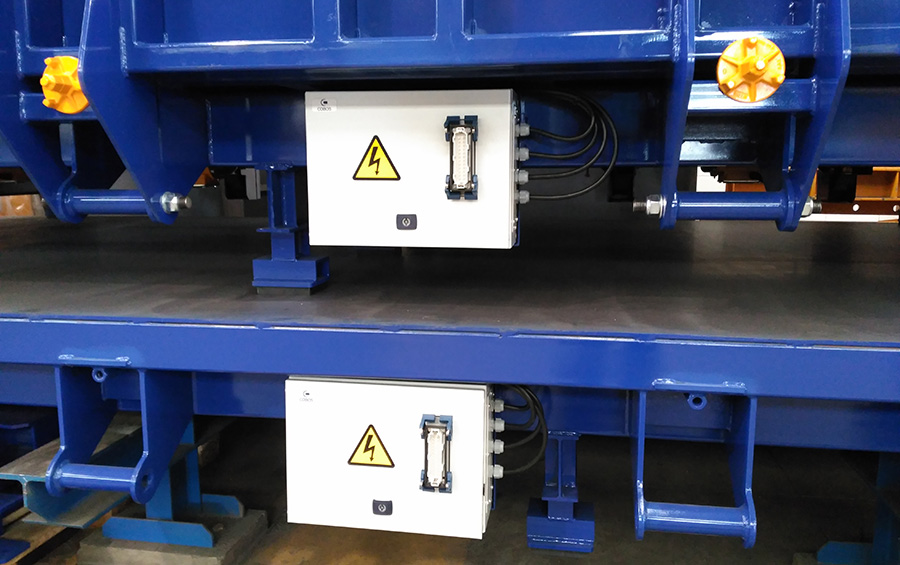

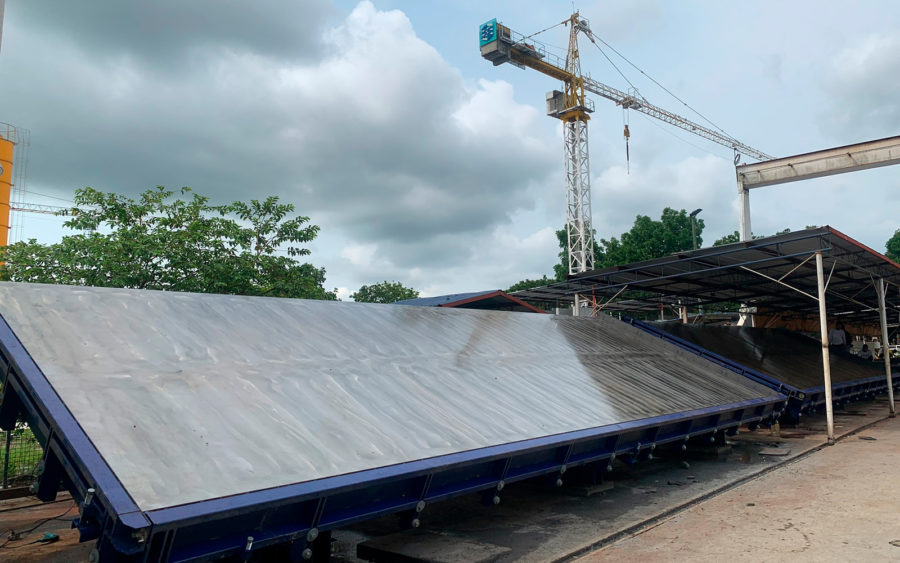

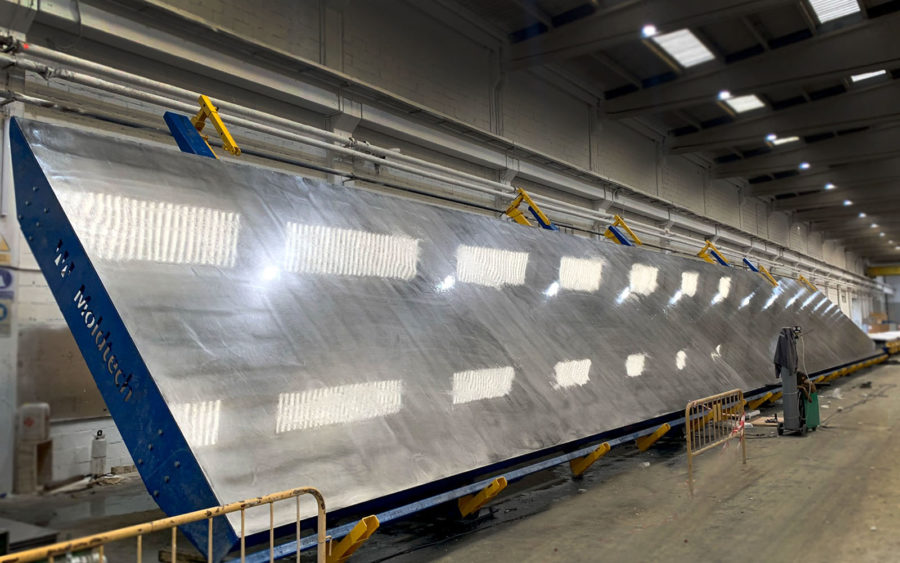

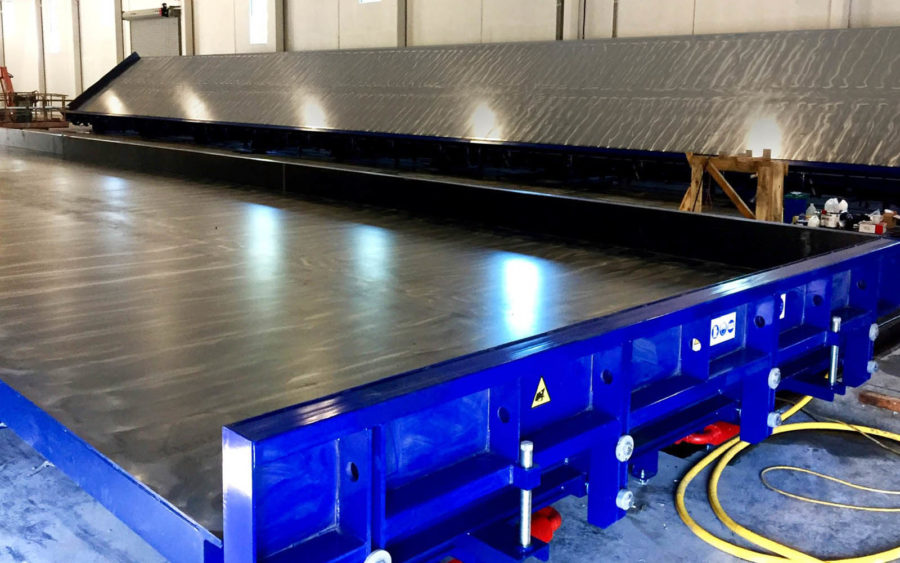

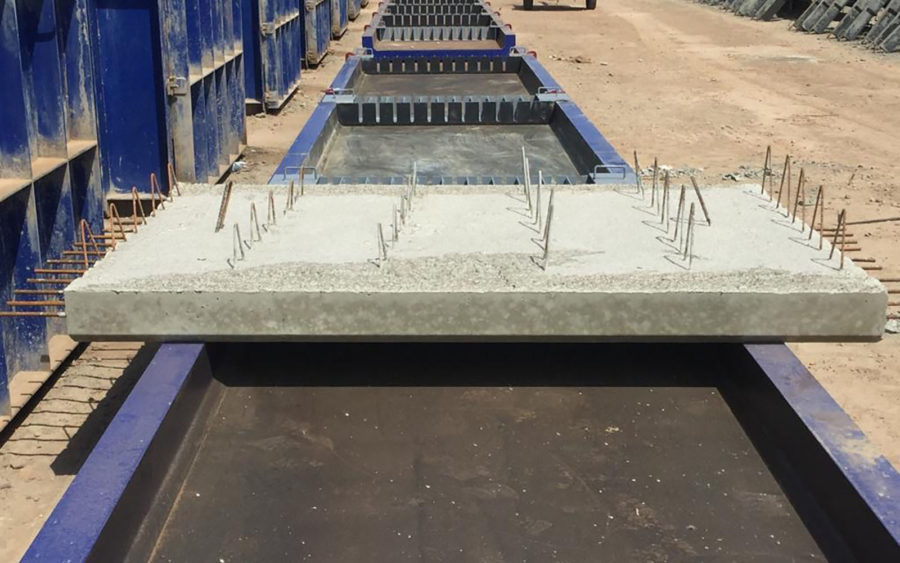

Molding surface length 45 m and width 2.4 m. Tensioning heads supporting 500 t.

Heating pipe system with isolation tarpaulin. Pneumatic vibration system.

Heating pipe system with isolation tarpaulin.

Pneumatic vibration system.

MOULD FOR PRESTRESSED ‘TT’ SLAB

2015 – INDIA

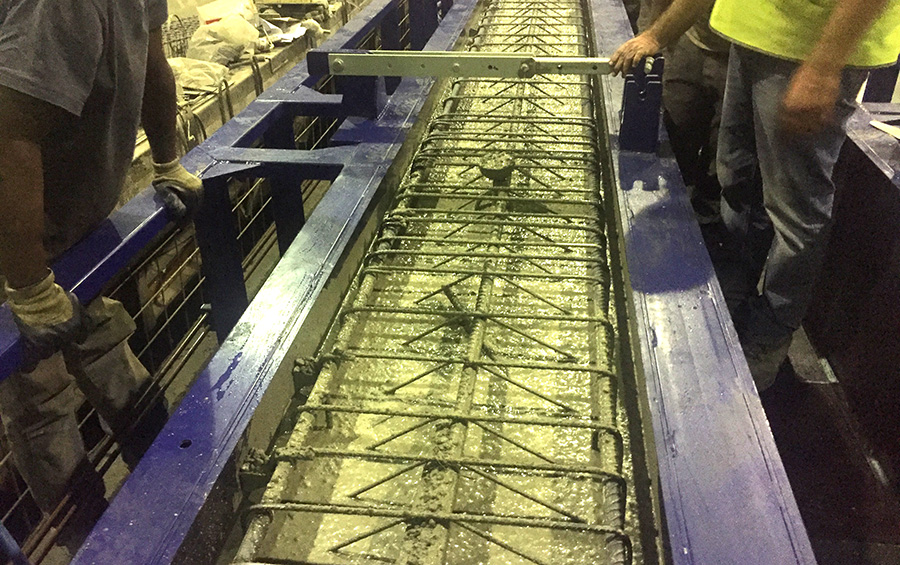

SUPPLY

Production capacity: 30,000 apartments in 2 years.

Design of factory ‘lay-out’.

Custom made design of moulds and accessories (notch boxes and corbels).

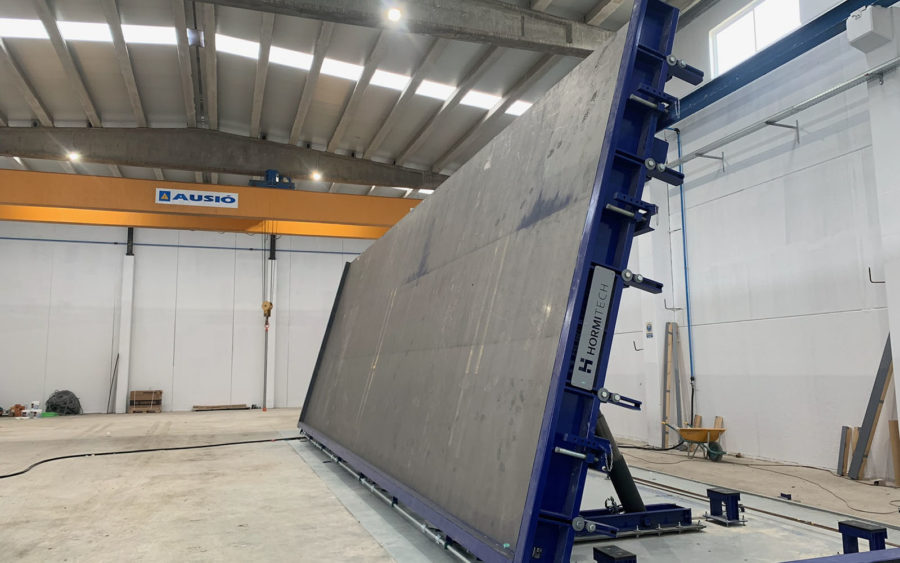

Tilting table 11,8 m x 3,5 m.

Concrete skip 2 m3.

Modular mould for elevator-shaft.

Planning of logistics process: design, production, transport, commissioning in 5 months.

On site production plant.

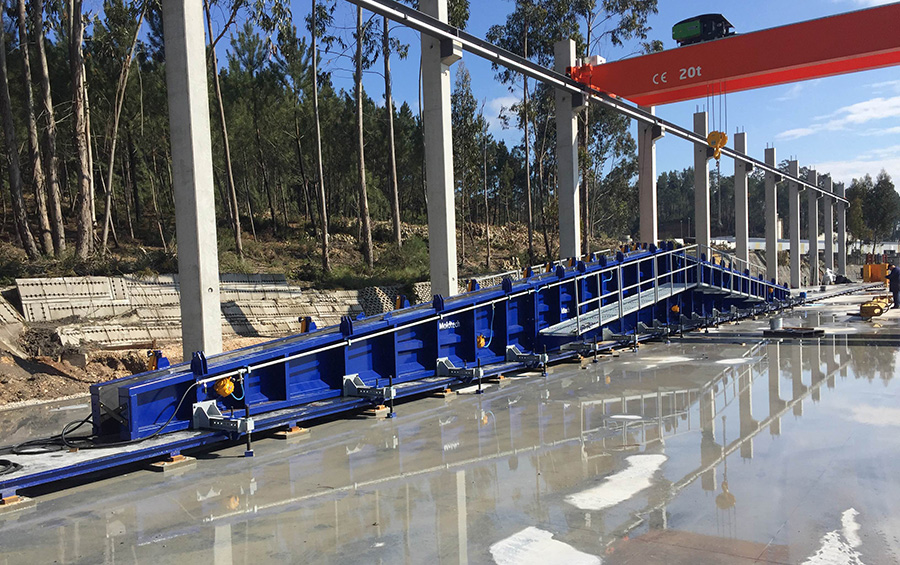

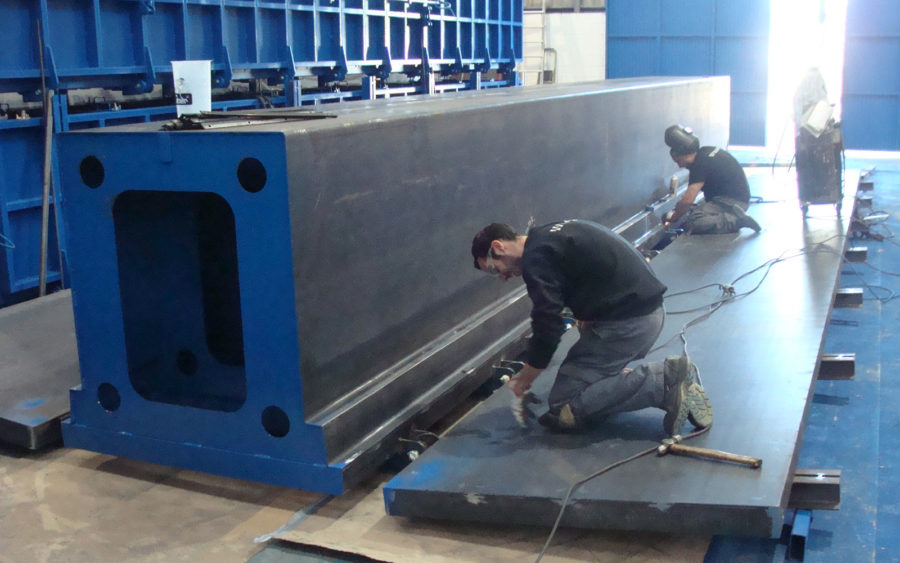

2000 METRES HYDRAULIC BEAM MOULDS INSTALATION FOR THE PRODUCTION OF BEAMS FOR RESIDENTIAL PROJECTS

2013 – INDIA

SUPPLY

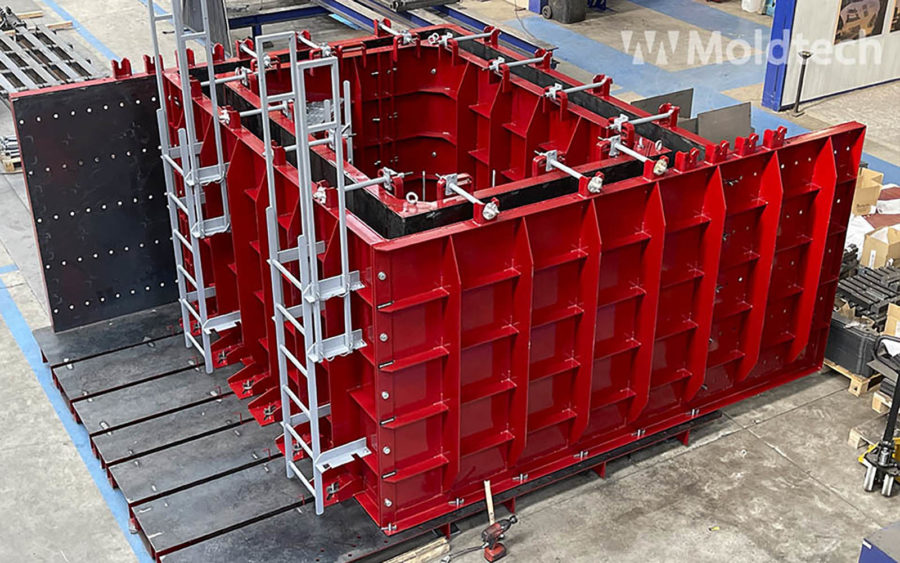

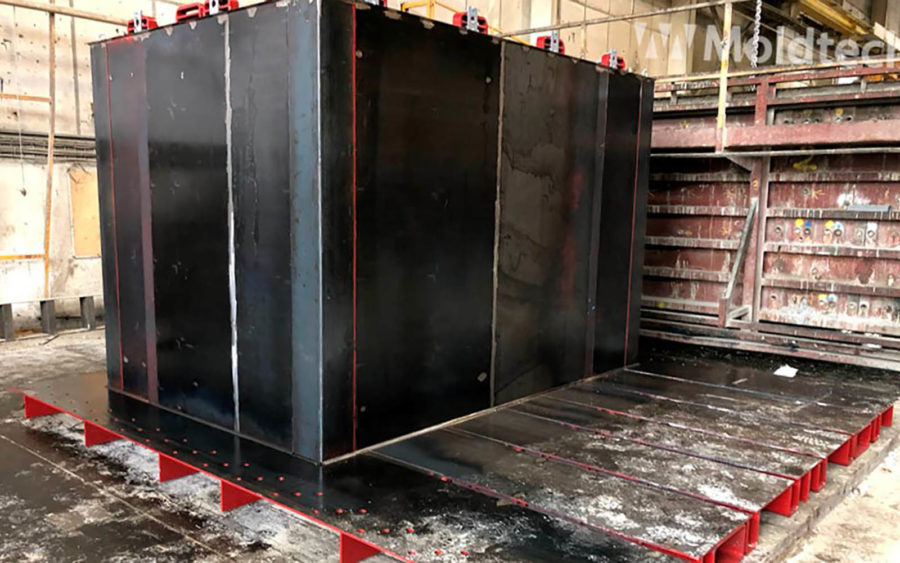

A total of 24 moulds for 3D bathroom units, with hydraulically shrinkable inner core.

It allows the production of monolithic 3D elements.

Two turning machines 180º, hydraulically movable shaft to adjust to different sizes.

COMPLETE FACTORY FOR 3D BATHROOM UNITS – PBU

2019 – SAUDI ARABIA

SUPPLY

A total of 12 tilting tables 12 m x 4 m.

1 stationary table 60 m x 2,5 m.

Concrete skip 2 m3.

TILTING TABLES

2014 – SAUDI ARABIA

SUPPLY

Automatic machines for filling and cleaning of tables and final product storage.

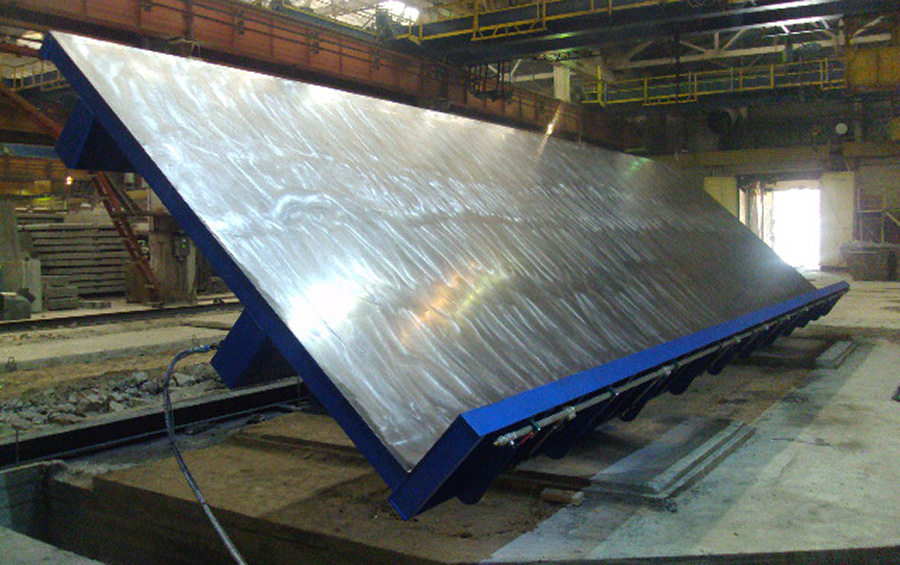

Tilting table of 42 x 3 m (137.7 x 9.8 ft).

AUTOMATIC MACHINES FOR CHAIN PRODUCTION OF PRECAST PANELS

2017 – ARGENTINA

SUPPLY

Serial production of concrete panels and slabs for the construction of various models of single-family houses.

MOLDETCH was the company chosen for the design, manufacture and installation of 2 tilting tables of 24 x 3.5 m.

Heigth adjustable bottom shutter that allows the production of panels up to 25 cm thick.

Pneumatic vibration system.

Polished casting surface with “mirror” finish for the production of very high-quality panels.

TILTING TABLES FOR RESIDENTIAL CONSTRUCTION

2020 – ARGENTINA

SUPPLY

1 tilting table of 40 m x 3 m.

Height adjustable bottom shutter that allows the production of panels up to 20 cm thick.

Pneumatic vibration system.

Polished casting surface with “mirror” finish for the production of very high-quality panels.

1 automatic concrete distributor.

1 cleaning machine.

1 stacking machine.

TILTING TABLE FOR RESIDENTIAL CONSTRUCTION

2015 – ARGENTINA

SUPPLY

Factory capacity: yearly output of 3,000 housing units of 60 sqm (645 sqft) average size.

Equipment supplied:

Twenty-one tilting tables for wall panels of 15.5 x 3 m (50.9 x 9.8 ft).

Three fixed tables 60 x 2.25 m (197 x 7.4 ft) for floor slabs, staircase moulds, equipment for lifting, transportation and storage of finished panels, and compressed air circuit.

Factory lay out design, productivity and feasibility calculations.

Commissioning, test production and training of local staff.

TURN-KEY PROJECT FOR PRECAST PLANT FOR THE CONSTRUCTION OF 3000 RESIDENTIAL HOUSING UNITS

2012 – VENEZUELA

SUPPLY

Two pouring buckets with electric vibrator and a motorized ruler, controlled by remote control.

Turning device with capacity up to 30 t (66,100 lbs) for safely turning box culverts 90º.

POURING BUCKETS AND BOX CULVERT TURNER FOR JENSEN PRECAST

2017 – USA

SUPPLY

Self-stressing tilting tables.

Dimensions 3.96 x 60.96 m (13 ft x 200 ft).

Hydraulic operated longitudinal shutters.

Pre-stressing capacity up to 280 t (620 kips).

Hydraulic open-close operation.

Total length 73.15 m (240 ft).

Capacity 640 t (1410 kips).

SELF-SUPPORTING TILTING TABLES FOR PRESTRESSED PANELS AND SLABS & MOULDS FOR ‘T/L/R’ BEAMS

2019 – USA

SUPPLY

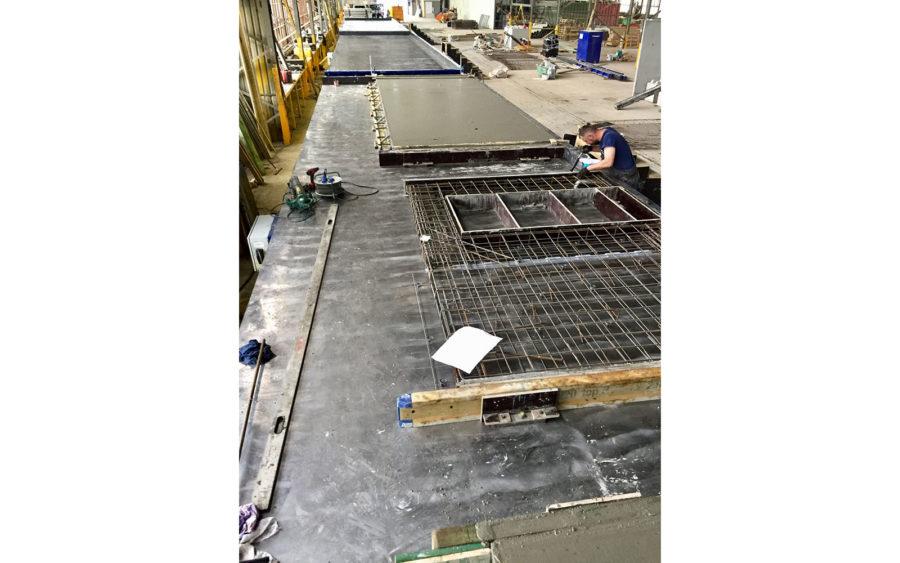

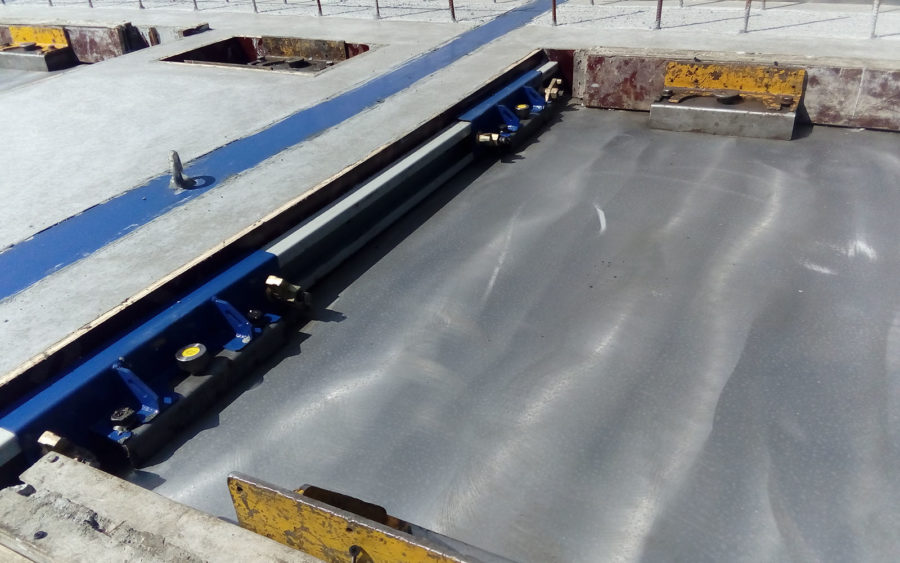

Two self-stressing tables of 150 x 2.4 m, with passive heads with a capacity of 110 t and its corresponding set of longitudinal and transversal formwork. Vibration by vibrotrack.

The supply includes a total of 3 wagons with portico structure on rails for a variety of tasks such as cleaning, application of release agent, strand pulling, transport of shutters, wire cutting and placement of canvas cover.

Two ‘Giraffe’ mobile concrete distributors with a capacity of 4 m³.

Fixed table of 150 x 4 m for the manufacture of foundation slab with hydraulic side shutter.

Four adjustable staircase moulds.

Pre-stressing equipment (stressing jack, hydraulic unit, wedges etc.).

EQUIPMENT FOR THE CONTRUCTION OF RESIDENTIAL BUILDINGS

2022 – USA

SUPPLY

A total of 6 moulds for the production of Prefabricated Bathroom Units (PBU).

A total of two different sizes with 6 moulds controlled by two hydraulic units.

Monolithic construction of the bathroom walls and floor after which the casted element is turned 180°.

Inner core with hydraulic retractable system for quick demoulding without the need for conical slope.

PBU MOULDS FOR MIAMI

2022 – USA

SUPPLY

Automated system which enables the factory to attain the objective of producing 4 homes per day includes a combination of a transversal shifter, non-motorized and motorized wheels which allow the pallets to move from one position to the next one. The whole moving system can be controlled by 1 operator.

The pods moving system allows the client to do all finishing work activities in line.

PODS MOVING SYSTEM

2021 – USA

SUPPLY

4 units of 3D mould of different configuration for prison cells production.

3D MOULDS FOR PRISON CELLS

2022 – USA

SUPPLY

Custom-made moulds for prison cells up to 11.6 x 6 m (38 ft x 20 ft).

Four cells.

Weight of casted element up to 60 MT (132,200 lbs).

PRISON CELLS (I)

2016 – URUGUAY

SUPPLY

Custom-made moulds for prison cells up to 11.6 x 6 m (38 ft x 20 ft).

Four cells.

Weight of casted element up to 60 MT (132,200 lbs).

PRISON CELLS (II)

2016 – URUGUAY

SUPPLY

Hydraulically tilting mould for L-shaped panels production.

2 moulds for Lego Blocks, with dimensions 1,6×0,8×0,8m.

Tilting table 12 m x 4 m.

Stacking machine.

Magnetic shuttering systems.

HYDRAULIC MOULD FOR L-SHAPED WALLS

2016 – SWEDEN

SUPPLY

2 Moulds for precast tower foundation.

Concrete skip.

MOULD FOR TOWER FOUNDATION

2016 – SWEDEN

SUPPLY

2 Moulds for precast pylon segments.

MOULD FOR PYLON SEGMENTS

2017 – SWEDEN

SUPPLY

10 Moulds for 3D elements (transformer stations).

Lifting devices.

Panel storage racks.

MOULD FOR TRANSFORMER STATIONS

2018 – SWEDEN

SUPPLY

2 Moulds for staircases 0,9 m width, fix size, to be used on the top of a vibrating table.

MOULD FOR STAIRCASES

2019 – SWEDEN

SUPPLY

1 Stationary table 8 m x 3,5m with:

Lower and 2 sides shuttering bands with adjustable height position for panel thickness from 100 to 300mm height.

STATIONARY TABLE

2020 – SWEDEN

SUPPLY

Table for L-shaped panels production up to 3,85 m height.

2 L-wall production per mould.

MOULD FOR L-SHAPED WALLS

2021 – SWEDEN

SUPPLY

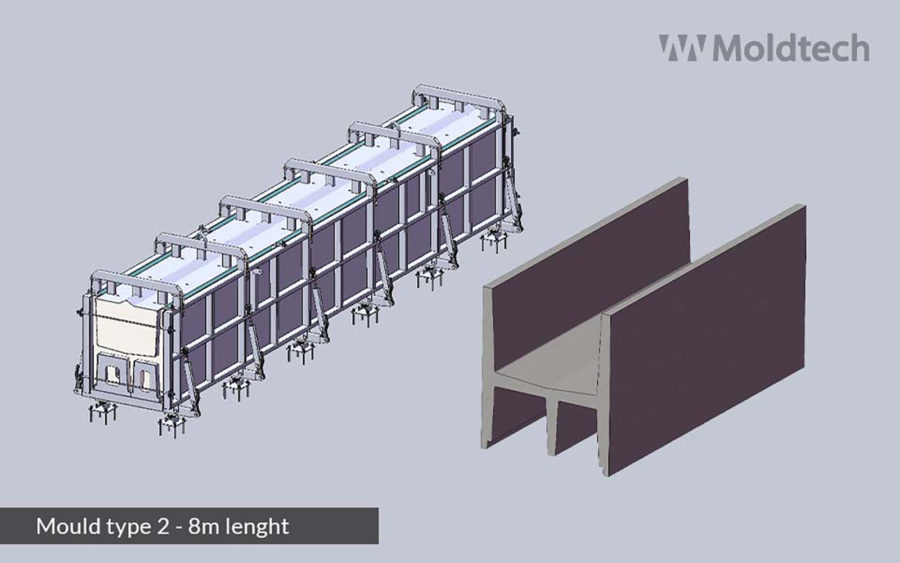

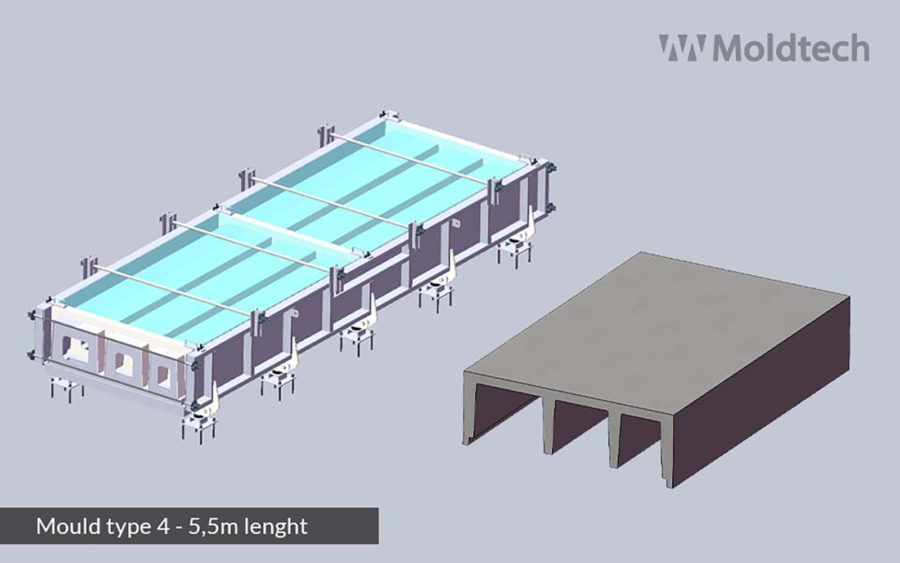

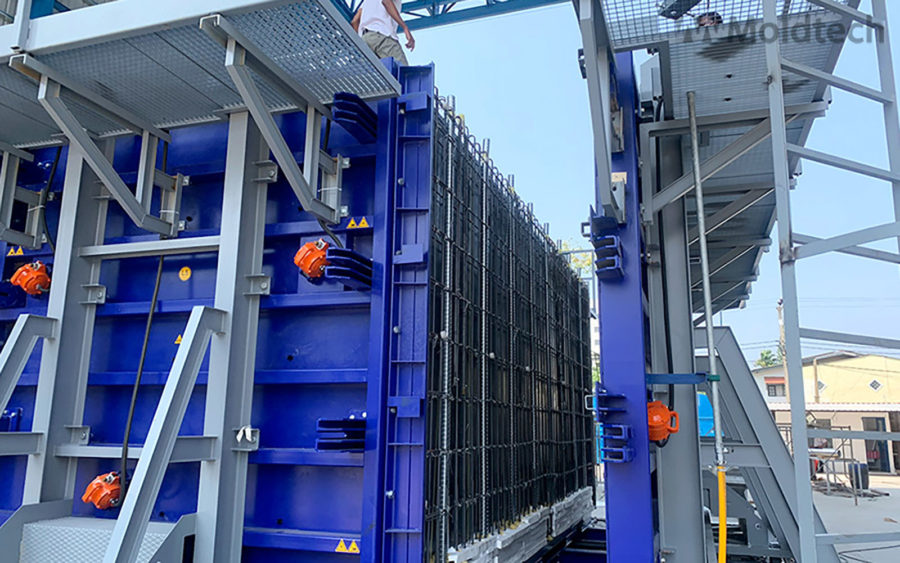

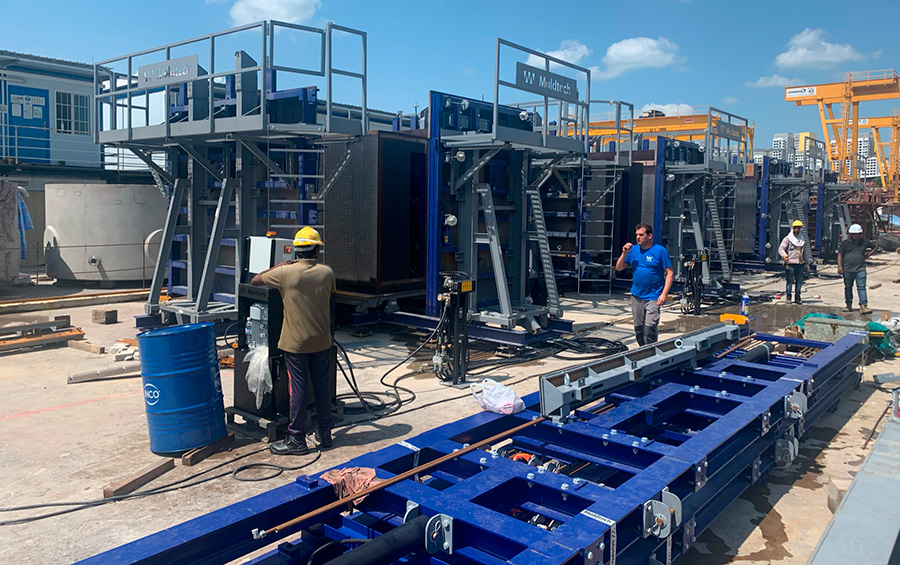

Conceived for the implementation of communication infrastructures.

Four moulds to produce different channel sections.

Special prefabricated elements with ‘H’ and ‘U’ shapes.

Daily production: 2-7 pieces, using intermediate dividing shutters.

Accessories: vibrotrack and hydraulic control unit.

MOULDS FOR PRECAST CABLE CHANNELS

2022 – SWEDEN

SUPPLY

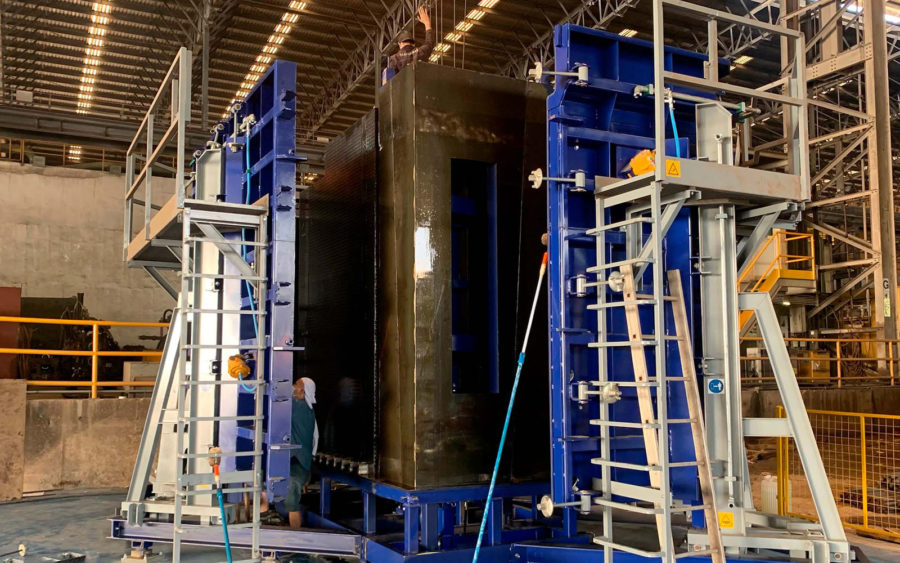

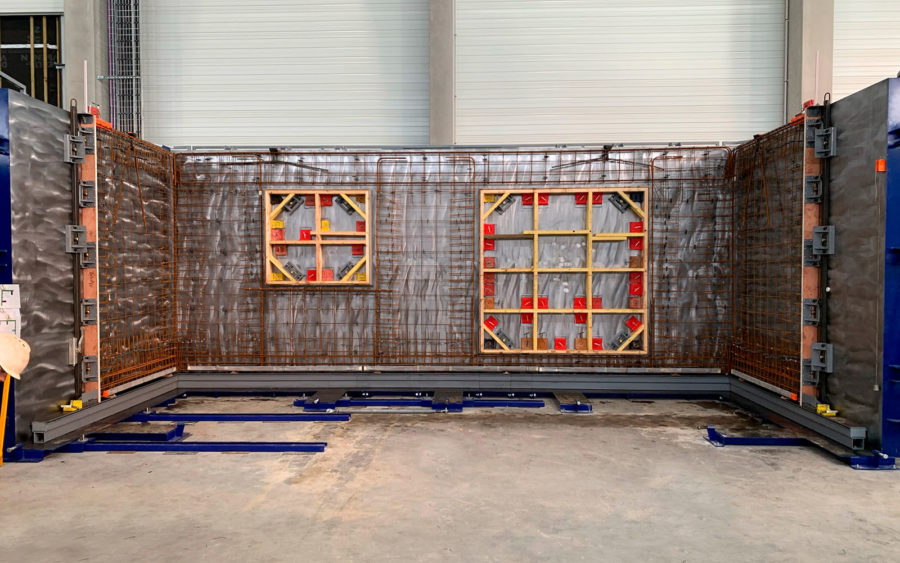

Conceived for the construction of residential buildings.

Max. dimensions of 6.55 m length x 3.24 m width x 3.1 m height.

Option to change wall thickness.

Inner core with hydraulic retractable system for rapid demoulding without the need for a conical slope. Production of 4 walls and top slab a monolithic element.

The floor slab is connected at a finishing table, completing its 6 sides.

After this the module is finished on the inside completing installations, finishes and furniture. Then the modules are transported to the building site, where they are structurally connected to each other.

The supply also included the door and windows shutters and two lifting beams with a maximum capacity of up to 35 t and six lifting points.

HYDRAULIC PPVC MOULD

2022 – SRI LANKA

SUPPLY

A total of 10 moulds for 3D volumetric precast concrete modules for bathroom units construction.

3D HYDRAULIC MOULDS FOR BATHROOM UNITS

2013 – SINGAPORE

SUPPLY

Four hydraulic moulds for the production of 3D prefabricated bathroom units of sizes 1.75 x 1.85 m (5.7 x 6 ft) inner dimensions and 2.3 m (7.5 ft) in height.

Two turning devices to turn the elements 180º with total capacity of 40 t (80,200 lbs).

3D MOULDS FOR PRECAST BATHROOMS

2017 – SINGAPORE

SUPPLY

Four hydraulic moulds for the production of 3D prefabricated bathroom units of sizes 1.75 x 1.85 m (5.7 x 6 ft) inner dimensions and 2.3 m (7.5 ft) in height.

Two turning devices to turn the elements 180º with total capacity of 40 t (80,200 lbs).

3D MOULDS FOR PRECAST BATHROOMS

2017 – SINGAPORE

SUPPLY

Six 180º hydraulic turning machines for 3D elements up to 40 t (88,200 lbs) weight.

Designed to meet the minimum and maximum dimensions of the 3D concrete modules.

Equipped with all visual and acoustic safety systems.

All movements are controlled by a hydraulic pump unit with a control board with all necessary safety switches.

HYDRAULIC TURNERS

2018 – SINGAPORE

SUPPLY

A total of 5 moulds for 3D volumetric precast concrete modules for residential construction.

Adjustable sizes up to 10 x 3.5 m dimensions.

Outer walls opened by hydraulic cylinders and inner core hydraulically shrinkable, commanded from hydraulic units with control board.

Heating system with air heaters and complete temperature control system.

Turning units 180º, adjustable to different sizes of modules.

HYDRAULIC MOULDS FOR 3D RESIDENTIAL MODULES – PPVC / PBU

2019 – SINGAPORE

SUPPLY

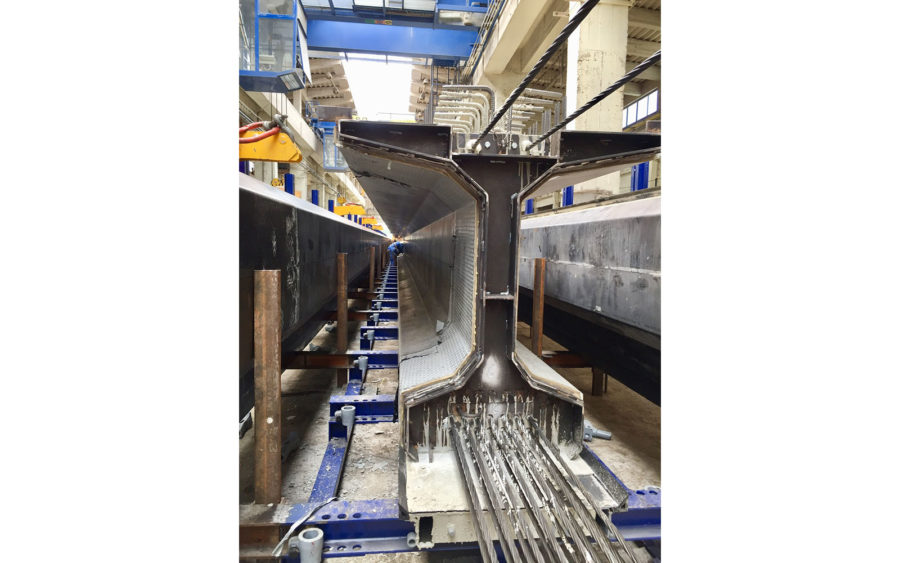

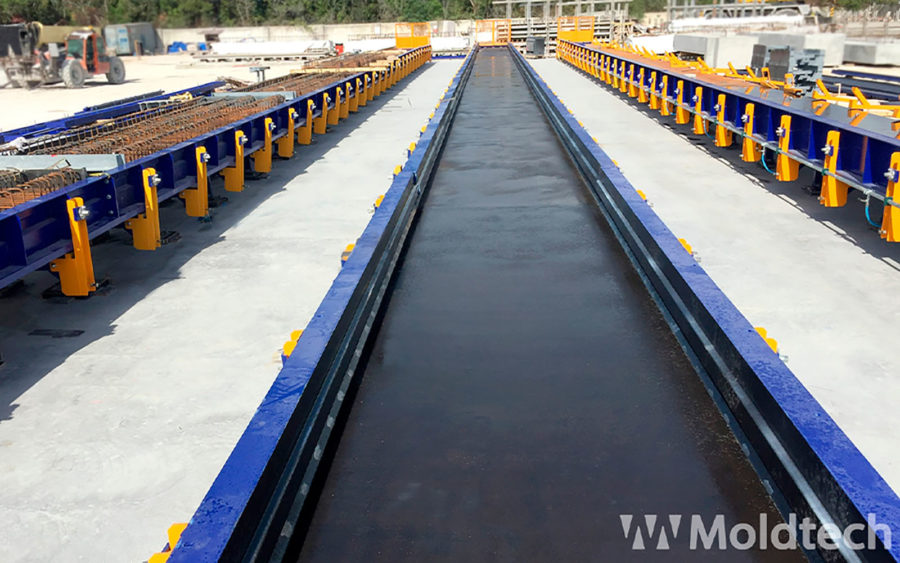

A total of 4 self-reacting prestressing lines with 125 m length and up to 1400 t capacity.

Four mould lines for prestressed bridge girders of 125 m length, with opening/closing by hydraulic cylinders.

They have an adjustable height for girders up to 2.2 m height. And with a heating system by finned pipe circuit and insulating tarpaulin covers.

‘Giraffe’ concrete transport and distribution vehicle with diesel engine and up to 4 m³ hopper capacity.

COMPLETE FACTORY FOR ROAD AND BRIDGE CONSTRUCTION(I)

2019 – ROMANIA

SUPPLY

Self-reacting fixed table for prestressed bridge decks.

‘MT20’ system for ‘DRYCAST’ for box culverts, up to 10 culverts daily production.

Moulds for bridge parapets.

COMPLETE FACTORY FOR ROAD AND BRIDGE CONSTRUCTION(II)

2019 – ROMANIA

SUPPLY

Hydraulic double column mould with 36 m length up to 80 x 80 cm section on each line.

With multi-corbel system for upper, bottom and lateral positions.

Hydraulic system for open-close operation.

Prestressing casting bed 120 m length, multi purpose for different types of pretressed elements.

Tilting table 24 x 4 m.

With electric vibration system.

COMPLETE PRECAST PLANT(I)

2019 – ROMANIA

SUPPLY

Pretressing Abutments System 1000 t, for all types of pretressed girders.

Self-reacting mould for ‘TT’ elements, with hydraulic opening/closing of outer mould sides.

Height and thickness of the ribs can be regulated.

Self-reacting prestressing system up to 400 t.

Concrete transport and distribution vehicle ‘Giraffe’ 3 m³ hopper capacity.

360º rotation movement and 18º vertical inclination.

Diesel engine.

COMPLETE PRECAST PLANT(II)

2019 – ROMANIA

SUPPLY

Mould with length of 62.5 m and with a prestressing capacity of 600 t.

Conceived for the construction of roofs of industrial buildings and warehouses.

Daily production up to 250 linear metres.

Two production lines in each mould.

Manufactures large quantity of units on the mould using longitudinal and transversal shutters. Includes electric vibration system and heating pipes. Removable upper part to produce different sections of purlins.

Improved surface quality of the beams by polishing casting surface.

BATTERY MOULDS FOR PRESTRESSED JOIST BEAMS

2021 – ROMANIA

SUPPLY

Hydraulic double mould for 32 m long columns, with interchangeable casting bed plates for width range from 300 to 1200 mm.

Nylon sliding paths for smooth opening and closing.

Top ties with handle.

Possibility of manufacturing columns with corbels on 3 sides in casting lane.

Hydraulic opening/closing system.

Hydraulic unit to control all movements.

Includes air vibration system (electric vibration system also possible as optional equipment).

Mechanical locks.

‘T’-beam battery mould with 2 working lines, 26 m long and 400 t of pre-stress, and with a depth of 60 cm.

HYDRAULIC DOUBLE COLUMN MOULD AND ‘T’- BEAM BATTERY MOULD

2021 – ROMANIA

SUPPLY

A universal casting bed with length of 62 m and width of 1 m.

Self-supporting mould with pre-stress capacity of 800 t.

Stressing jack and de-tensioning cylinders.

‘I’-beam sides with length of 30 m and 800-1000- 1200-1400 mm high.

‘Delta’ beam sides with length of 30 m.

‘L/T’ beam sides with length of 16 m.

INSTALLATION FOR INDUSTRIAL PLANT

2021 – ROMANIA

SUPPLY

Four moulds for the manufacture of underpasses with a maximum height of 3.2 m to be built observing the country’s norms and regulations.

Specifically, four sets of mould sides and eight bases were supplied.

This equipment provides the client with a high production capacity of up to 12 pieces per day (19.2 linear meters).

In addition, MOLDTECH designed this mould in such a way that the client can manufacture prefabricated elements of different heights as the equipment was designed in a modular way, thus offering a versatile solution capable of adapting to a wide variety of production requirements.

MOULDS FOR CIVIL WORKS

2021 – ROMANIA

SUPPLY

Double moulds to manufacture New Jersey barriers 3 m length.

Stationary table 12 m x 1,5 m to produce floor slabs and panels.

Mould for Lego type blocks 1 m x 2 m x 1 m.

MOULDS FOR NEW JERSEY BARRIERS AND STATIONARY TABLE

2017 – ROMANIA

SUPPLY

Mould sides for I girders production, 28 m length.

MOULDS FOR I GIRDERS

2019 – ROMANIA

SUPPLY

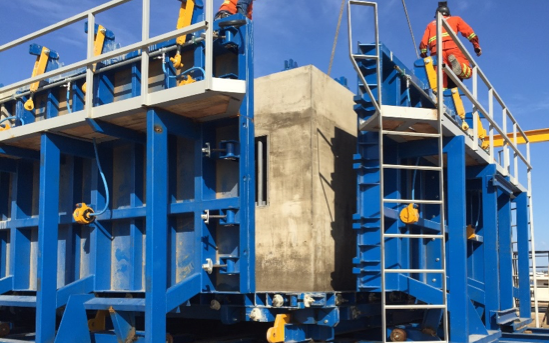

Mould for box culverts consisting of:

- 4 inner corners moulds.

- 4 outer corners moulds.

- Supplements set.

- 2 bases.

SPECIAL MOULD FOR BOX CULVERTS

2020 – ROMANIA

SUPPLY

2 Double moulds to manufacture New Jersey barriers 6 m length.

MOULDS FOR NEW JERSEY BARRIERS

2021 – ROMANIA

SUPPLY

Battery mould to manufacture concrete segmental box culverts, with the capacity to produce up to 8 casted elements per day (9.6 linear metres).

Double mould for the manufacture of precast concrete wings. These pieces are placed at the beginning and at the end of the culvert and segmental culverts galleries, concluding with them the complete work of the water canalization. This mould can produce up to 4 pieces per day.

MOULDS FOR WATER CHANNELS

2021 – ROMANIA

SUPPLY

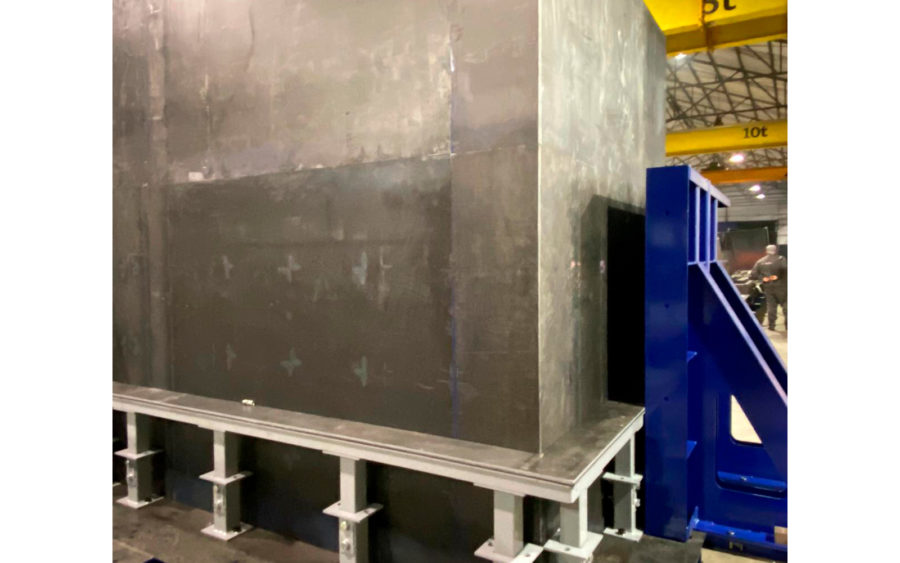

Vertical battery mould with two casting cells, for the production of architectural panels max 12 x 2.5 m (39.3 x 8.2 ft).

ARCHITECTURAL PANELS IN VERTICAL BATTERY MOULD

2016 – PORTUGAL

SUPPLY

DIRECTION: hydraulic, frontal.

WEIGHT: approximately 9,500 Kg (20,943 Ibs), depending on models.

HOPPER CAPACITY: 3 m³

MAXIMUM ANGLE OF ENDLESS CONVEYOR: 18º to the vertical.

MAXIMUM DISPLACEMENT SPEED: 10 km/h.

MAXIMUM DISPLACEMENT SLOPE: 5º

ENGINE POWER: diesel 70 kW.

ROTATION: 180º for 120 S and 360º for 120.

‘GIRAFFE’ SYSTEM FOR CONCRETE TRANSPORT AND POURING

2020 – PORTUGAL

SUPPLY

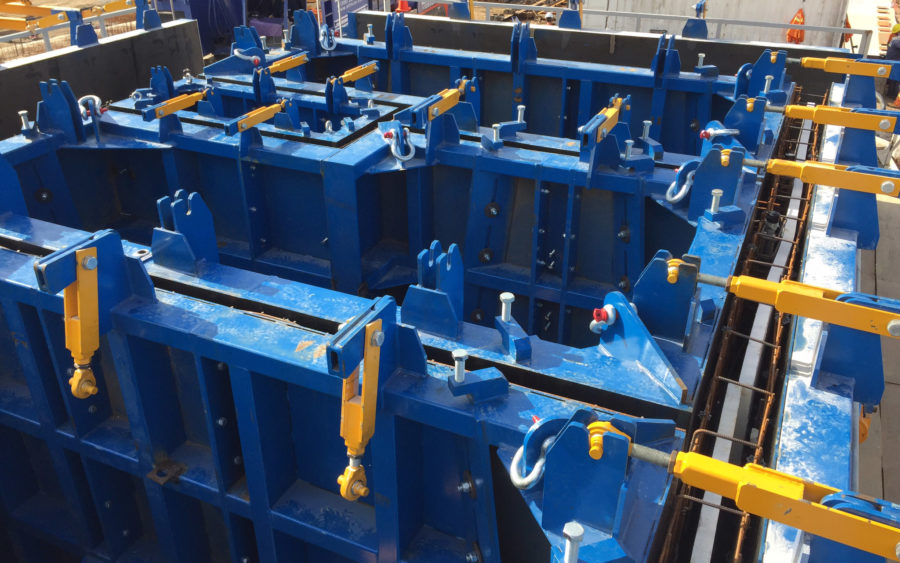

Modulated system of steel formworks designed for the production of precast half-frames by using wet cast concrete.

HALF-FRAMES IN MODULAR MOULDS

2010 – PORTUGAL

SUPPLY

Modulated system of steel formworks designed for the production of precast box culverts by using wet cast concrete.

BOX CULVERTS IN MODULAR MOULDS

2012 – PORTUGAL

SUPPLY

Modulated system of steel formworks designed for the production of precast box culverts by using wet cast concrete.

Accessories:

Mobile concrete skip 2 m3 – 2 units.

Modular shuttering.

BOX CULVERTS IN MODULAR MOULDS

2014 – PORTUGAL

SUPPLY

Pit foundation prestressing system, capacity 600 tn.

PIT FOUNDATION PRESTRESSING SYSTEM

2017 – PORTUGAL

SUPPLY

Capacity of 3 m³.

Emptying through 9 pneumatic gates, adjustable opening and discretionary selection.

Electric-pneumatic system: longitudinal movement and different track changes.

Chute and oscillating screed.

Systems controlled from a fixed control on a central platform or from a remote control.

CONCRETE DISTRIBUTOR FOR PALLET CIRCULATION SYSTEM

2020 – PORTUGAL

SUPPLY

- Universal casting bed of 100 m length.

- Pit foundation prestressing system 600 tn.

- Mould sides for delta beam up to 30 m length.

- Mould sides for I girder up to 20 m length.

- Moulds for water channels.

- Tilting table 50 m x 2,5 m.

- Concrete skip 2 m3.

- Magnet shuttering systems.

COMPLETE FACTORY FOR INDUSTRIAL PROJECTS

2016 – PORTUGAL

SUPPLY

15 m long hydraulic double mould for the production of columns.

HYDRAULIC DOUBLE MOULD FOR COLUMNS

2017 – PORTUGAL

SUPPLY

13 pallets for panels production of 16 m x 4 m built with structural profiles and finished contact sheet polished.

With load capacity to manufacture thicknesses of panel up to 25cm.

These trays can be used on the system of existing carousel.

1 Transport wagon for pallets.

1 Lifting beam for panels, 25 t.

PALLETS FOR PANLES PRODUCTION

2022 – PORTUGAL

SUPPLY

For the manufacture of stairs with a maximum of 19 steps, 2 optional landings and a maximum width of 2 m.

The size of the steps is manually adjustable by means of spindles and phenolic formwork planks, with maximum and minimum dimensions.

The width of the stairs is adjustable by means of interchangeable wooden bottoms (not supplied with the mould) and adjustments of the height supplements incorporated in the structure.

FLEXIBLE STAIRCASE MOULD FOR RESIDENTIAL WORK

2020 – PORTUGAL

SUPPLY

Modulated system of steel formworks designed for the production of precast box culverts by using dry cast concrete.

Accessories:

Concrete skip 2 m3.

BOX CULVERTS IN MODULAR MOULD MT-20

2014 – POLAND

SUPPLY

Modulated system of steel formworks designed for the production of precast box culverts by using wet cast concrete.

BOX CULVERTS IN MODULAR MOULD

2016 – POLAND

SUPPLY

Three tilting tables 16 x 4 m.

Heating system with finned pipe circuit.

Vibration system with electric vibrators and frequency converter.

Concrete bucket with hydraulic discharge gate.

TILTING TABLES

2019 – POLAND

SUPPLY

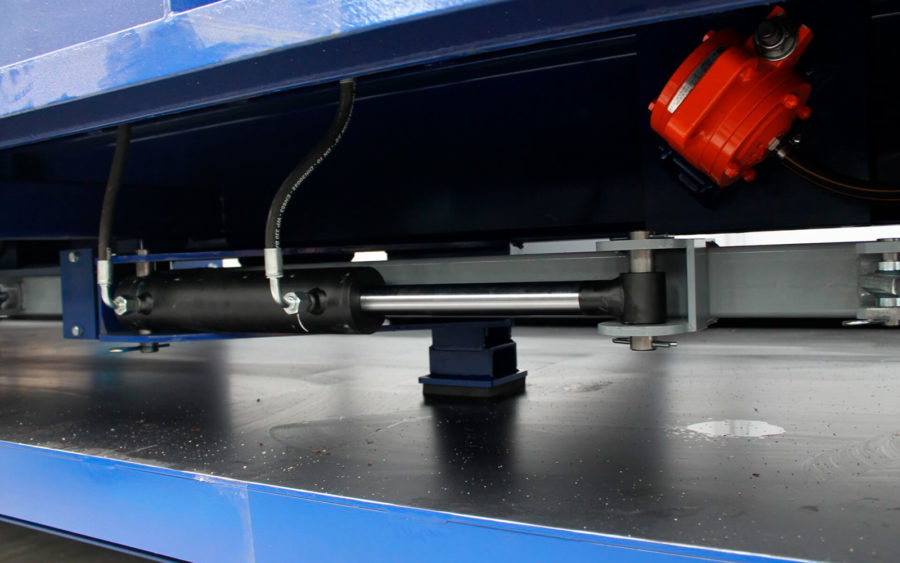

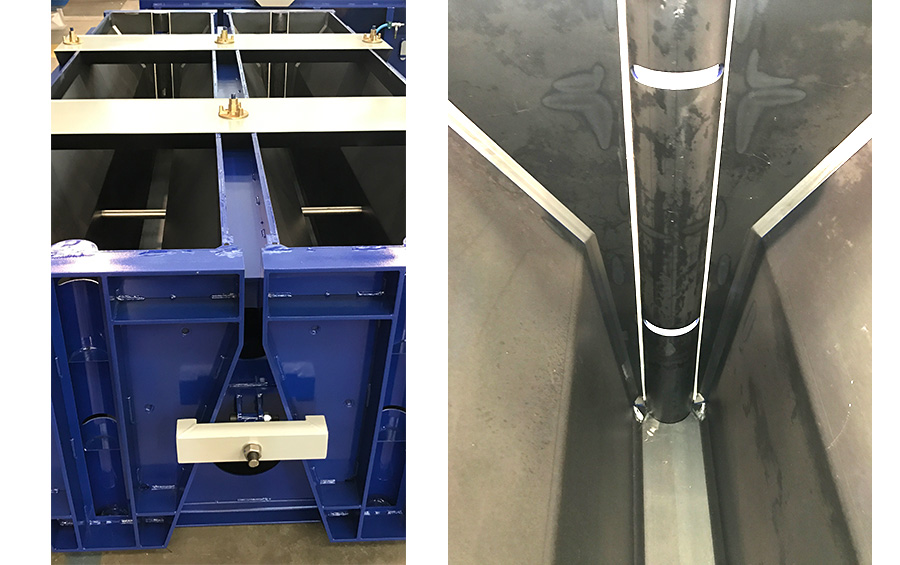

Inner core with hydraulic shrinkage system.

The core is activated by a hydraulic cylinder to shrink and expand.

The core is inserted into the mould and expands completely.

Concrete is poured into the mould and sets.

Stripping: the outer faces are opened, the core is hydraulically contracted and pulled out to remove the finished channel piece.

SPECIAL MOULD FOR DRAIN CHANNELS

2020 – POLAND

SUPPLY

1 Stationary tables/pallets for balconies 12×2,5m. Vibration system for stationary tables with 6 electric vibrators.

40 Magnetic frame system for plywood shutters, with 2,5 m length, including 2 adapters and 2 magnets 900kg.

STATIONARY TABLE

2021 – POLAND

SUPPLY

Tilting table of 16 x 4.5 m (52.4 x 14.7 ft) with automatic vibration and heating.

Set of frames with magnetic fixation for wood formwork.

TILTING TABLE FOR CLOSURE PANELS

2017 – NORWAY

SUPPLY

Stationary table of 25 x 4.5 m with automatic vibration and heating.

Set of frames with magnetic fixation for wood formwork.

STATIONARY TABLE FOR PANELS

2018 – NORWAY

SUPPLY

1 Tilting table 35 m x 3,5 m with accessories.

MT20 SYSTEM FOR THE DRY CAST BOX CULVERT PRODUCTION

2019 – MEXICO

SUPPLY

This machine consists of a modular mould to produce culverts from 1.5 x 1.5 to 3 x 4 m.

The system has 10 modular work bases and a new pressing system hydraulic system that together with an electrical vibration system distributed throughout the exterior and interior mould contour, ensures that the final product has an unmatched finish quality.

In addition to being flexible in measurements and not requiring any civil works, this system allows to be able to manufacture on site campaigns or move the mould through different factories in an environment.

MT20 SYSTEM FOR THE DRY CAST BOX CULVERT PRODUCTION

2020 – MEXICO

SUPPLY

This universal bed system has a fixed base system that allows the production of beams with a base up to 80 cm. The tensioning head system has slackening cylinders and the corresponding tensioning equipment, for 12 and 15 mm diameter strands.

A modular length ‘delta’ beam mould, which will allows the customer to produce ‘delta’ beams up to 34 m in length. These beams will be used for the construction of industrial and logistics buildings.

A beam mould for ‘L’, ‘T’ and rectangular sections, variable width, 1 m high, and 24 m long. This mould will work on the universal prestressing bed system and will be used to produce all types of slab support beams.

To solve the drainage of industrial roofs, MOLDTECH has provided the client with a self-supporting mould of a 15 m long ‘H-Channel’ beam, with a fixed section of 40 x 50 cm, and a 150 t prestressing system. This channel beam will be in the lower part of the ‘delta’ beams to collect rainwater from the roof, and discharge through vertical pipes fixed to the columns.

UNIVERSAL PRESTRESSING BED SYSTEM OF 1000 TONS

2020 – MEXICO

SUPPLY

Side moulds for LTR girder, up to 24 meters length.

Side moulds for I girder, up to 24 meters length, modular height adjustment.

Self-reacting mould for H beams, 15 meters length.

SIDE MOULDS FOR BEAMS

2020 – MEXICO

SUPPLY

2 Tilting tables 36 m x 3,8 with hydraulically regulated sides.

Magnet shuttering systems.

TILTING TABLES

2021 – MEXICO

SUPPLY

Tilting table of 60 m length, for panels production of a variable height between 2,957 mm and 4,300 mm and a variable thickness from 100 to 250 mm. The sides are hydraulically adjustable. The table is supplied with pneumatic vibration system and heating system.

TILTING TABLES

2022 – MEXICO

SUPPLY

Turn-key project.

Four tilting tables for the production of the wall panels.

Table for the production of the roof slab.

Book type table for the production of the floor slab.

PLANT FOR THE PROD.OF PRECAST POWER TRANSF.STATIONS

2018 – MOROCCO

SUPPLY

70 m universal casting bed system.

Streassing heads for 600 t of pre-stress.

Moulds for ‘I’ and rectangular beams types, 35 m length.

Auxiliary pre-stressing equipment such as stressing jacks, and de-tensioning units.

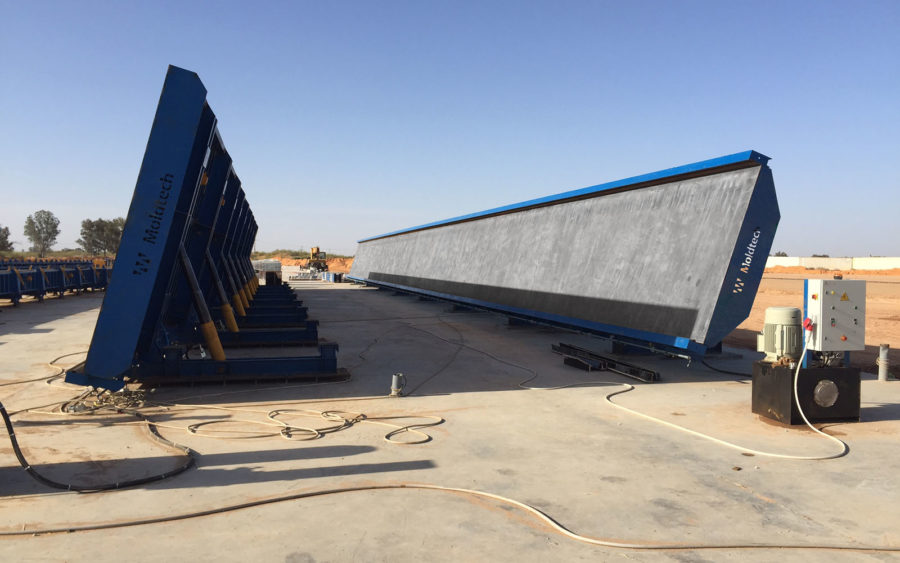

PRESTRESSED BEAM PRODUCTION SYSTEM

2020 – MOROCCO

SUPPLY

Equipment for the production of precast elements for the construction of the extension of the new Rabat Airport terminal.

100 m long self-stressing ‘TT’ slab mould.

80 m long universal casting bed with stressing heads for 600 t and mould sides to produce ‘L’, ‘T’ and rectangular beams.

Single lane column mold with corbels.

Tilting table.

NEW PRECAST PLANT FOR RABAT AIRPORT

2022 – MOROCCO

SUPPLY

Tilting table of 53,2 m for the production of L-shaped panels.

Accessories:

Hydraulic control unit.

Air vibration system.

TILTING TABLES

2013 – MOROCCO

SUPPLY

4 Tilting tables for the production of panels.

1 Turning table.

1 Stationary table.

Accessories:

Hydraulic control unit.

Air vibration system.

Concrete skip 2 m3.

Lifting beams 32 t and 9 t.

TILTING TABLES

2017 – MOROCCO

SUPPLY

Casting bed of 65 m (213 ft) in length and 1.2 m (3.9 ft) in width.

Tensioning heads for 600 t (1322.7 KIPS) with self-stressing structure of 65 m (213 ft) in length.

Mould sides for casting of ‘Y’ girder of 1 m in height and 32 m (105 ft) in length.

Mould sides for casting of ‘TL’ girder of 1 m (3.2 ft) in height and 21.5 m (70.5 ft) in length.

Mould sides for casting of ‘H’ girder of 1 m (3.2 ft) in height and 21.5 m (70.5 ft) in length, with

or without side corbels.

Versatile column mould of 25 m (82 ft) in length. Hydraulic opening and closing of the mould.

Hydraulic adjusting of the column section, from 0.5 x 0.4 m (1.64 x 1.3 ft) up to 0.9 x 0.7 m (2.95 x 2.3 ft).

Three sets of corbels on four sides.

FACTORY FOR PRE-STRESSED ELEMENTS

2016 – MALTA

SUPPLY

Stationary table 60 m x 3 m for preslabs production.

Magnetic shuttering systems.

STATIONARY TABLE

2016 – MALTA

SUPPLY

4 double moulds, 8 m length, for New Jersey barriers production.

Air vibration systems.

MOULDS FOR NEW JERSEY BARRIERS

2020 – MALTA

SUPPLY

Two moulds for ‘I’ beams 60/81/101 cm (24/32/40 inches) and 25 m (32.8 ft) length.

Mould for ‘TI / TL’ beams (h) 119 cm (47 inches), 25 m (82 ft) length.

Double column mould 40/51 x 40/51/61 cm (16/20 x 16/20/24 inches), 35.4 m (115 ft) length.

Self-supporting mould for ‘TT’ slabs 60 m (196 ft) length.

Two tilting tables of 35.4 x 3.5 m (117 x 11.4 ft) and 47.2 x 2.5 m (156 x 8.2 ft).

Fixed battery mould 11 m (36 ft) for 8 beams ‘T-35’.

COMPLETE FACTORY FOR INDUSTRIAL BUILDINGS (I)

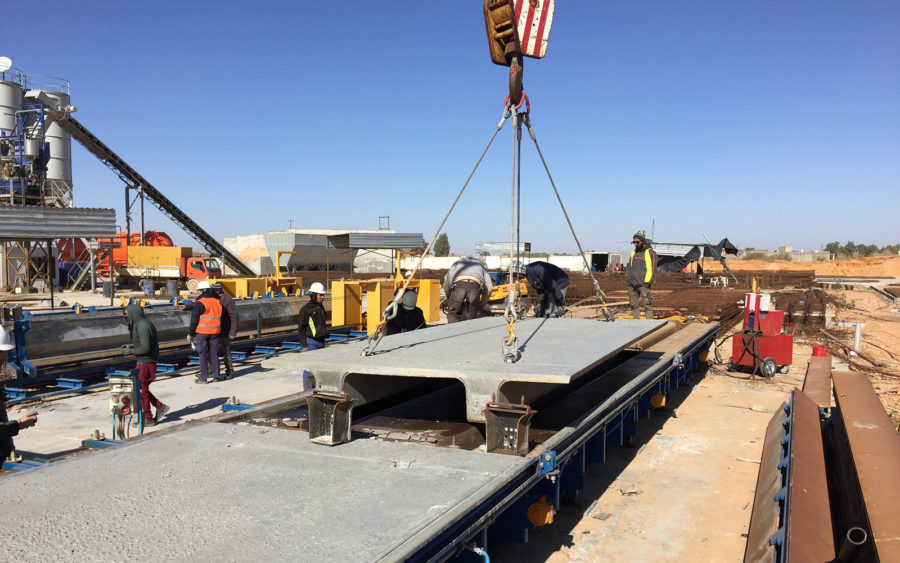

2016 – LYBIA

SUPPLY

Two moulds for ‘I’ beams 60/81/101 cm (24/32/40 inches) and 25 m (32.8 ft) length.

Mould for ‘TI/TL’ beams (h) 119 cm (47 inches), 25 m (82 ft) length.

Double column mould 40/51 x 40/51/61 cm (16/20 x 16/20/24 inches), 35.4 m (115 ft) length.

Self-supporting mould for ‘TT’ slabs 60 m (196 ft) length.

Two tilting tables of 35.4 x 3.5 m (117 x 11.4 ft) and 47.2 x 2.5 m (156 x 8.2 ft).

Fixed battery mould 11 m (36 ft) for eight beams ‘T-35’.

COMPLETE FACTORY FOR INDUSTRIAL BUILDINGS (II)

2016 – LYBIA

SUPPLY

This project included the construction of motorway bridges using ‘Aashto IV’ and ‘Aashto VI’ pre-casted and post-tensioned girders.

The ‘Aashto IV’ girders have a length of approx. 30 m and weigh around 48 t whereas the ‘Aashto VI’ come in a length of approximately 40 m and a weight of 81 t.

The total supply for these items included 400 m of casting bed and 200 m of mould sides.

RING ROAD PROJECT (I) -‘AASHTO’ GIRDERS FOR BRIDGES

2021 – KENYA

SUPPLY

Apart from the ‘Aashto’ girders moulds, the client also requested so-called ‘Plank’ moulds which fabricate pre-stressed hollow core deck slabs.

The cavity is made by leaving a metal insert in the concrete for which MOLDTECH designed special tools to compensate for the upward movement and ensure that they stay in place.

A total of 130 m of casting bed was delivered together with 8 hinged mould sides with height of 60cm and a length of 14.7 m.

The stressing head has a capacity of 435 t and includes slackening cylinders for the de-tensioning of the strands prior to cutting them.

RING ROAD PROJECT (II) – SPECIAL MOULDS FOR BEAMS

2021 – KENYA

SUPPLY

Four double book moulds for casting panels up to 28 cm (11 inches) consisting of natural stone, concrete layer, insulation material and concrete layer with smooth finish.

Three tilting tables 12 x 4.5 m (39.4 x 14.8 ft), with special formwork for protruding bars.

A fixed table for floor slabs.

Tailor-made manufactured frequency converter for total control of electric vibration.

‘Lay-out’ design and commissioning.

MANUFACTURE AND INSTALLATION OF DOUBLE BOOK MOULDS AND TILTING TABLES FOR SPECIAL PANELS

2013 – ISRAEL

SUPPLY

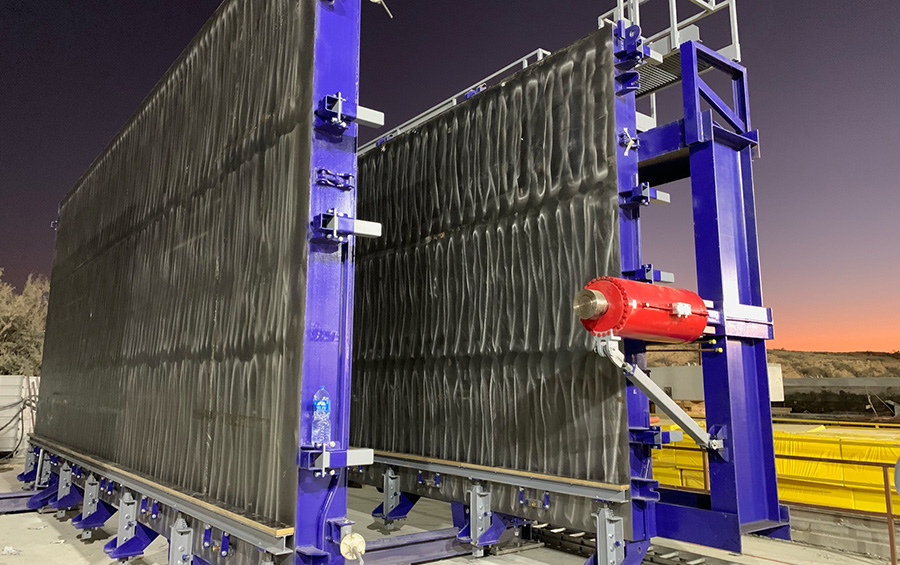

The mould allows our clients to make panels up to 10 m long and with a height of 4 m.

With the help of mechanical extenders, the side shutters can be located inwards thereby shortening the panel length.

At the same time the mould allows for adjustment of the panel height using telescopic supports.

The opening and closing movements of the panels are carried out by 2 electric motors controlled from a control panel, while 2 high-capacity hydraulic cylinders are used to tighten the cavities before the concrete is poured.

At full capacity the mould can cast 10 panels at the same time with a panel thickness up to 350 mm.

VERTICAL BATTERY MOULD FOR PANELS

2021 – ISRAEL

SUPPLY

Mould for making box culvert wet cast 4000 mm x 4000 mm x 3000 mm.

MOULD FOR BOX CULVERTS

2018 – ISRAEL

SUPPLY

Vertical battery mould with 5 casting lines with maximum size 10 m x 4 m.

Includes:

5 bottom baseplates with adjustable height for panels of 120mm thickness.

VERTICAL BATTERY MOULD FOR PANELS

2020 – ISRAEL

SUPPLY

3D – PBU mould for bathroom modules.

Inner core and outer walls driven by a hydraulic system with hydraulic cylinders controlled from a control unit with control panel.

Adjustable for different part sizes.

Heating system for curing with fan heaters and integrated control system.

180º turner with a capacity for 35 t.

3D-PBU MOULD AND 180º TURNER

2020 – HONG KONG

SUPPLY

Universal casting beds and mould sides for the production of “ASSHTO type I beams with stressing heads of 600 t (1322 KIPS).

Double column moulds.

Moulds of main beams of 16 m (5.2 ft).

Self-stressing ‘double T’ mould of 36 m (118 ft) long and width 2.4 m (7.9 ft).

Analysis of the production process and design of factory ‘lay-out’.

COMPLETE FACTORY FOR THE PRODUCTION OF(PRE-STRESSED)CONCRETE ELEMENTS FOR INDUSTRIAL AND COMERC.BUILDINGS AND BRIDGES

2014 – HONDURAS

SUPPLY

Modular moulding system for box culverts production.

Mould sides and universal casting bed system for bridge girders production.

Moulds for New Jersey barriers production.

FACTORY FOR CIVIL WORK PROJECTS

2015 – HONDURAS

SUPPLY

Self-supporting steel structure with a capacity of 800 t (1,760 KIPS) of pre-stress, and a length of 70 m (230 ft).

25 m (82 ft) modular mould for the production of ‘I’ girder.

SELF-SUPPORTING SYSTEM FOR BRIDGE GIRDERS

2017 – HONDURAS

SUPPLY

Moulds for channels for different sections.

Fixed tables for the production of top closing slabs of the channels.

Modular moulds for box-culverts for dimensions up to 3 x 2 m.

Universal bed system of 105 m length.

Moulds for ‘I’ beams for bridges including auxiliary equipment.

Special formworks for circular columns of viaducts and bridges.

EQUIPMENT FOR THE CONSTRUCTION OF ROAD INFRASTRUCTURES

2020 – GUINEA CONAKRY

SUPPLY

Moulds for round columns of different sections.

Stationary tables for half-slabs.

EQUIPMENT FOR ROUND COLUMNS

2014 – GUINEA CONAKRY

SUPPLY

6 Moulds for box culverts.

1 Equipment “Giraffe” for transporting and pouring of concrete.

4 moulds for “U”-shaped channels.

MOULDS FOR INFRASTRUCTURE ELEMENTS

2021 – GUINEA CONAKRY

SUPPLY

New fixed table of 75 x 2.40 m size for the production of non-prestressing pre slab, to use in residential buildings.

Supplied with a system of hydraulically adjustable sides, which allows to quickly adjust the height of the pre slab or the panels to be produced. The thickness is variable from 50 to 200 mm.

With a polishing completion of the sheet that is in contact with the self-levelling concrete, which ensures a perfect finish of the exposed face of the slab.

NEW SPECIAL FIXED TABLE FOR PRESLAB

2019 – FRANCE

SUPPLY

The MOLDTECH tilting table of 12.5 m enables the company to produce precast concrete elements of up to a thickness of 30 cm and with a load of 750 kg/m2.

French precasters normally use the fixed tables as a general casting surface where all kinds of different concrete elements are casted using magnetic shuttering. These elements can be architectural, structural or façade elements. This table, with a size of 13.5 x 5 m and a load capacity of 750kg/ m2, features manually adjustable lateral shuttering of 30 cm height and offers great versatility for the production of flat and linear concrete elements.

The classic double beam mould, widely used in France but in this case features hydraulic opening and closing. This mould has a length of 8 m and will cover future production needs. Each line can produce a maximum section of 1.5 x 1.5 m. However the longitudinal mid panel can be removed allowing casting widths of 3.1 m and height up to 1.5 m.

All surfaces directly in contact with the concrete have a special polish so self-leveling concrete can be used. The mould has also gangways in accordance to the safety regulations.

FACTORY EXPANSION IN NORTHWEST FRANCE

2020 – FRANCE

SUPPLY

Special moulds for rooms for residential buildings, which allow to produce precast concrete elements with different doors and windows, and to leave embedded elements.

The residential unit is constructed using “ending” modules and “intermediate” modules.

The ending modules consist of: 2 outer sides, 2 lower sides, 2 bases, 2 height supplements and 2 transversal shutters.

The intermediate modules consist of: 2 outer side panels, 2 inner side panels, 2 bases and 2 transversal shutters.

Two assembly tables.

COMPLETE RESIDENTIAL PLANT

2021 – FRANCE

SUPPLY

Produces 3D monolithic elements, without tapering of the walls.

Built with modular length and width adjustment to produce different sizes.

Hydraulically shrinking inner core.

Hydraulically closing of outer mould.

Includes air vibration system.

The finished element is demoulded in a record time.

The mould allows producing elements with different doors and windows position and embedded elements; it also allows special configurations according to the customer’s request.

High quality monolithic 3D elements using self-compacting concrete, produced with great efficiency and flexibility.

HYDRAULIC MOULD PPVC FOR RESIDENTIAL ELEMENTS

2021 – FRANCE

SUPPLY

According to this specification, the mould supplied by MOLDTECH, is an easy operated mould, consisting in 2 sides in the shape of a ‘L’ frame allowing the sections and thickness of the element to be cast to be modified, as well as a set of 2 bases to produce 2 box culverts per day.

The minimum interior section of the mould is 3 x 2 m, and the maximum is 3 x 3 m, having intermediate sections every 0.25 m.

The mould maintains the same height in all sections, while the thickness of the precast element could be also modified from 180 to 305 mm.

NEW MOULD FOR BOX CULVERT WET CAST

2021 – FRANCE

SUPPLY

Tilting table of 37 x 3.5 m.

Hydraulic side shutters.

Top shutter with height of 150 mm high and length of 37 m.

Accessories: transversal shutters of different sizes.

Hydraulic control unit.

Pouring bucket of 1.5 m³.

TILTING TABLES

2022 – FRANCE

SUPPLY

2 Tilting tables 12 m x 4 m with accessories.

TILTING TABLES

2019 – FRANCE

SUPPLY

3 Special stationary tables (with 5 lines each) to produce 20 cm x 20 cm columns.

BATTERY MOULD FOR COLUMNS

2020 – FRANCE

SUPPLY

1 Hydraulic mould for columns, 24 m length.

1 Hydraulically regulated double mould for columns.

1 Tilting table.

EQUIPMENT FOR INDUSTRIAL BUILDINGS

2021 – FRANCE

SUPPLY

Two tilting tables with dimensions of 11.8 x 4 m (38.8 x 13.14 ft) for manufacturing façade panels.

Lower shuttering band with height adjustment.

Magnetic shuttering formworks.

Magnetic frame system for plywood shuttering.

TILTING TABLES AND SHUTTERING FORMWORKS

2017 – PHILIPPINES

SUPPLY

1 vehicle “Giraffe” for transporting and pouring of concrete.

VEHICLE GIRAFFE

2019 – PHILIPPINES

SUPPLY

1 Stationary table for bridge decks production, 105 m length, 2,39 m width.

4 Moulds for bridge fascias.

STATIONARY TABLES FOR BRIDGE DECKS

2019 – PHILIPPINES

SUPPLY

Two tilting tables with dimensions of 12 m x 4 m for manufacturing façade panels.

Lower shuttering band with height adjustment.

Magnetic shuttering formworks.

TILTING TABLES

2020 – PHILIPPINES

SUPPLY

Two sides of 66 m (216.5 ft) length with adjustable height from 385 to 900 mm (15 inches to 35

inches).

Moulding frame of 66 m (216 ft) length.

Supporting bridges for moulding frame.

Stressing heads.

SIDES AND MOULDING FRAME FOR PRE-STRESSED OMEGA BEAM

2015 – SPAIN

SUPPLY

Prestressing abutments system 1250 t, with double passive anchor 2500 t. With hydraulically activated sleeves to block and unblock the slackening of cylinders.

Prestressing abutments system 400 t. With hydraulically activated sleeves to block and unblock the slackening of cylinders.

EQUIPMENT FOR BEAMS PRODUCTION

2019 – SPAIN

SUPPLY

Concrete distributor 3 m³ capacity with oscillating screed. Double control platform, concrete distribution by 9 independently activated pneumatic gates. Sideways motion of hopper on crane system and portal crane structure with hydraulic sideway shifter for changes of tracks.

Transport wagon for finished panels, with up to 24 t capacity.

Self-reacting prestressing casting bed with 600 t capacity and 75 m length, with interchangeable baseplates.

Mould for ‘T’ beams with modular height adjustment 1-1.2 m.

EQUIPMENT FOR INDUSTRIAL PRODUCTION

2019 – SPAIN

SUPPLY

Two tilting tables of 36 x 4 m, controlled through a hydraulic unit and by means of a touch screen.

Remote control to execute all processes (movement system, elevation and vibration) in a simple and intuitive way, by a single operator.

The tables are designed to manufacture concrete panels in a width range from 2 to 4 m and with a wall thickness from 16 to 30 cm.

Hydraulic top shutter.

Electric vibration system.

Hydraulic power unit.

TILTING TABLES FOR PANELS PRODUCTION

2020 – SPAIN

SUPPLY

Self-supporting battery of beams with 4 working lines of 66 m long and 400 t tensioning head.

De-tensioning equipment.

16 tapes.

BATTERY MOULD FOR BEAMS

2021 – SPAIN

SUPPLY

A total of 2 tilting tables of 14 x 4.4 m, with bottom and side shutter of 31 cm.

Hydraulic unit to operate 2 tables.

TILTING TABLES

2022 – SPAIN

SUPPLY

54 m of sidewalls on universal track for 1 m wide beams.

33 m of side panels on universal track for 1.5 m wide beams.

45 m of hydraulic mould for 2 m wide beams.

EQUIPMENT FOR THE PRODUCTION OF AASTHO BEAMS

2019 – SLOVAKIA

SUPPLY

Mould for I girders with 24m length. With modular height adjustment: 270, 750, 850 and 950mm.

EQUIPMENT FOR THE PRODUCTION OF I GIRDERS

2020 – SLOVAKIA

SUPPLY

54 m of sidewalls on universal track for 1 m wide beams.

33 m of side panels on universal track for 1.5 m wide beams.

45 m of hydraulic mould for 2 m wide beams.

EQUIPMENT FOR THE PRODUCTION OF AASTHO BEAMS

2019 – SLOVAKIA

SUPPLY

Two complete beds with stressing heads of 1000 t (2,204 KIPS).

Fixed table for preslabs of 70 m (230 ft).

Fixed table for the production of retaining walls of 15 x 2.5 m (49.2 x 8.2 ft).

Two “Giraffe” units for transport and pouring of the concrete.

‘MT20’ equipment for the production of dry cast box culverts of sizes 1 x 1 up to 3 x 4 m (9.1 x 13.1 ft).

COMPLETE FACTORY IN MEDELLÍN FOR THE PRODUCTION OF PUBLIC WORKS ELEMENTS (I)

2018 – COLOMBIA

SUPPLY

Two ‘I’ beam moulds of 45 m (146.7 ft) length and height of 2.20 m (7.26 ft).

COMPLETE FACTORY IN MEDELLÍN (II) -BEAM MOULD FOR ROADS AND BRIDGES

2018 – COLOMBIA

SUPPLY

Self-stressing mould of 134 m (440 ft) in length and 4.3 m (14 ft) in width for ‘TT’ slabs.

Tensioning capacity of 450 t (992 KIPS).

MOULD FOR TT SLABS

2017 – CANADA

SUPPLY

The size of the tables, 34 x 4 m was designed specifically in order to optimize the factory lay-out and make production as efficient as possible. The tables feature lower and side height adjustable shutters which allows the client to produce insulated panels up to a thickness of 1 ft.

For an optimum compaction of the concrete the tables incorporate a pneumatic vibration system consisting of 21 vibrators located strategically against the under part of the casting surface.

The heating system is also located under the casting plate and consists of finned piped connected to a hot water boiler.

The supply is completed with a hydraulic unit from which one can control the tilting movement of both tables.

TILTING TABLES

2019 – CANADA

SUPPLY

Mould for making box culverts wet cast to make elevator shaft elements in the size ranges mentioned on page 4: 204”x 76” and 222” x 104”.

MOULD FOR ELEVATOR SHAFT

2020 – CANADA

SUPPLY

Self-reacting table for TT slabs production, 60 m length.

SELF-REACTING TABLE

2021 – CANADA

SUPPLY

6 Stationary tables (pallets) of 12 m x 4,5 m with air pneumatic vibration systems and different types of sides.

STATIONARY TABLES

2021 – CANADA

SUPPLY

Mould for making box culverts wet cast to make elevator shaft elements in the size ranges 204”x 76” and 222” x 104”.

MOULD FOR ELEVATOR SHAFT

2021 – CANADA

SUPPLY

Six pallets of 40’ x 15’ with pneumatic vibration.

Side shutters with height supplements.

PALLETS FOR CARROUSEL LINE

2022 – CANADA

SUPPLY

Moulds for the production of drain channels.

Fixed tables for the production of pre-slabs for bridges.

Formwork for drainage channels.

INSTALLATION OF EQUIPMENT FOR CIVIL WORK

2020 – BURKINA FASO

SUPPLY

Moulds for the production of drain channels.

Fixed tables for the production of pre-slabs for bridges.

Formwork for drainage channels.

INSTALLATION OF EQUIPMENT FOR CIVIL WORK

2016 – BURKINA FASO

SUPPLY

Moulds for the production of drain channels 0,8 m x 0,8 m and 1 m x 1 m.

Stationary tables for the production of drain channels lids, 12 m length.

Double moulds for New Jersey barriers.

2 Giraffe vehicles for transporting and pouring concrete 3 m3.

INSTALLATION OF EQUIPMENT FOR CIVIL WORK

2018 – BURKINA FASO

SUPPLY

The project includes equipment to produce electric poles according to the regulations of SONELGAZ, a historic electric power and gas operator in Algeria.

SONELGAZ has been and is a promoter of electricity and gas distribution networks throughout the Algerian territory.

MOLDTECH has studied the design of the equipment meticulously, so that the client has production systems that allow user-friendly use, in addition to having the help of hydraulic opening and closing systems.

The moulds meet the regulations for prestressed electric poles type RC250, CC400 and CC630. These moulds allow to produce in three different lengths, 9, 11 and 12 m.

PRESTRESSED ELECTRIC POLES ACCORDING TO SONELGAZ REGULATIONS

2020 – ALGERIA

SUPPLY

1 Tilting table 11,8 m x 3 m for panels production max up to 20 cm width.

Magnetic shuttering systems.

TILTING TABLE

2016 – ALGERIA

SUPPLY

2 Tilting table 7,5 m x 4 m for panels production.

1 Stationary table 7,5 m x 3,4 m.

1 Twin wall table 9,2 m x 3 m.

Magnetic shuttering systems.

Concrete skip 2 m3.

Lifting beams 32 t and 9 t.

PRODUCTION OF PANELS

2018 – ALGERIA

SUPPLY

The expansion of the Nassau cruise port requires the use of pre-stressed deck panels.

For the production of these panels Moldtech designed the corresponding self-stressing fixed tables prepared for a prestress force of up to 140 MT.

The panels have typically a length of 6.70 m and a width of 1.52 m. The height of the panel is either 30 or 45 cm whereas the profile can be straight or incorporating a keyway.

MOLDTECH came up with a solution which enables the same table to produce all the different panel varieties providing maximum flexibility to the client.

A total of 3 tables are being installed, each with a length of 49 m. Transversal shutters and a pneumatic vibration system complete the supply for this project.

FIXED TABLES FOR PRE-STRESSED PANELS

2021 – THE BAHAMAS

SUPPLY

Moulds for the production of box culverts.

Turning machine 90º and 25 tn.

BOX CULVERTS AND TURNING MACHINE

2020 – AUSTRALIA

SUPPLY

Mould for the production of pre-stressed L-shaped beams.

L-SHAPED BEAM

2022 – AUSTRALIA

SUPPLY

MT20 system for dry cast box culvert, size: From 1,2×1,2m to 2,4×2,4m, with 300mm increments. Maximum Height 1,2m.

Able to produce half-culverts (min span 1,2m). Adjustable thickness: 140-180-220-260mm.

MT-20

2021 – AUSTRALIA

SUPPLY

Moulds for the production of box culverts.

Moulds for the production of bridge wings.

5 concrete skips.

BOX CULVERTS AND BRIDGE WINGS

2014 – BENIN

SUPPLY

3 Modulated system of steel formworks designed for the production of precast box culverts by using wet cast concrete.

1 Mould for water channels segments.

1 Stationary table of 11,8 m length for water channels lids.

BOX CULVERTS AND WATER CHANNELS MOULDS

2016 – CAMEROON

SUPPLY

6 units of moulds to produce staircases.

MOULDS FOR STAIRCASES

2015 – CURAZAO

SUPPLY

Moulds for the production of drain channels.

Fixed tables for the production of lids for the channels.

MOULD FOR DRAINAGE CHANNELS WITH LIDS

2014 – IVORY COAST

SUPPLY

30 units of double moulds of 2 m long for the production of New Jersey barriers.

MOULDS FOR NEW JERSEY BARRIERS

2015 – COSTA RICA

SUPPLY

MT-20 equipment consisting of inner and outer formwork with a set of bottoms to produce vibropressed dry cast box culverts in different sizes. Additionally, it complements with the turning device with the capacity to turn precast box culverts up to 15 t.

MT-20 AND TURNING MACHINE FOR BOX CULVERTS

2011 – CHILE

SUPPLY

Modulated system of steel formworks designed for the production of precast box culverts by using wet cast concrete.

BOX CULVERTS IN MODULAR MOULD

2017 – ECUADOR

SUPPLY

12 double moulds of 3 m long with supplements.

10 moulds for “Lego” blocks 1500 mm x 600 mm x 600 mm.

MOULDS FOR NEW JERSEY BARRIERS AND LEGO BLOCKS

2016 – EL SALVADOR

SUPPLY

75-meter-long casting bed that allows the production of beams with a base of up to 80 cm.

The tensioning heads of 600 t.

A modular set of laterals for the manufacture of Delta beams up to 24 meters in length.

MOULD FOR DELTA BEAM

2022 – GEORGIA

SUPPLY

2 units of single moulds for staircases production.

MOULDS FOR STAIRCASES

2016 – GIBRALTAR

SUPPLY

Pre-stressing system of 1000 t and side moulds for T-L beam to be installed on the existing universal casting bed.

MOULD FOR T-L BEAM

2022 – LATVIA

SUPPLY

2 Turners 180º for precast elements, maximum capacity 40Tn. With hydraulic adjustment to elements of different sizes. Includes hydraulic pump unit with electrical control board to activate all movements.

TURNING MACHINES

2020 – MALASIA

SUPPLY

1 Mould for producing double U-shaped elements.

Width: 2360mm

Height: 1400mm

Length: 1210/1220 mm

MOULD FOR “DOUBLE U” SHAPED CHANNELS

2015 – OMAN

SUPPLY

4 double moulds of 3 m long with supplements.

NEW JERSEY BARRIERS

2013 – PERU

SUPPLY

Modular mould sides for Delta beam production, L max = 30 m.

Accessories:

Air vibration system.

MOULD SIDES FOR DELTA BEAM

2015 – PERU

SUPPLY

Automatic distribution and vibration system.

Cable throwing machine.

Shuttering systems.

PRODUCTION LINE FOR PRESTRESSED ROAD SLABS

2014 – RUSSIA

SUPPLY

2 Tilting tables of 25 m x 4 m.

Accessories:

Hydraulic control unit.

Air vibration system.

TILTING TABLES

2012 – RUSSIA

SUPPLY

6 Tilting tables of 12,5 m.

Accessories:

Hydraulic control unit.

Electric vibration system.

TILTING TABLES

2012 – RUSSIA

SUPPLY

6 Tilting tables of 12,5 m x 3,8 m.

Accessories:

Hydraulic control unit.

Electric vibration system.

Heating system.

Automatic concrete distributor.

TILTING TABLES

2014 – RUSSIA

SUPPLY

5 Moulds for “U” – shaped elements.

5 Vertical battery mould for panels.

3 Stationary table for façade panels 11 m x 4 m.

MOULDS FOR PRECAST FAÇADE ELEMENTS

2021 – SWITZERLAND

SUPPLY

Mould sides for bridge girders production.

Universal casting bed system.

MOULD FOR BRIDGE GIRDERS

2014 – TOGO

SUPPLY

2 Modulated system of steel formworks designed for the production of precast box culverts by using wet cast concrete.

BOX CULVERTS IN MODULAR MOULD

2017 – UNITED KINGDOM

SUPPLY

2 Modulated system of steel formworks designed for the production of precast box culverts by using wet cast concrete.

BOX CULVERTS IN MODULAR MOULD

2017 – UNITED KINGDOM

SUPPLY

4 Hydraulic casting bed systems of different length.

4 self-reacting prestressing system of different capacity.

SELF-REACTING PRESTRESSING SYSTEMS

2022 – UNITED KINGDOM